How to Manage Compressed Air Systems During High-Demand Events

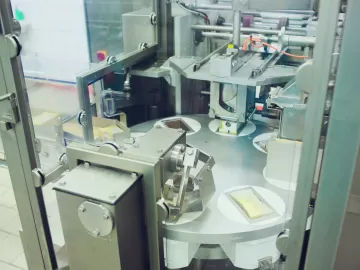

One of the challenges with compressed air system design is dealing with periodic large flow demands. Food and beverage manufacturers are among those process industries that often face these events. Adding in the compressed air demands of onsite packaging further adds to the task.