Utilities monitoring paired with machine learning models can reliably predict anomalies, prompting action that can prevent waste and optimize resource use.

Many of the decisions that industrial and discrete manufacturing companies make every day determine the sustainability of their operations. Resources like compressed air, electricity, gas, water and steam power much of the production equipment that’s essential to a company’s success. How they use that equipment, as well as how and when they choose to maintain it, affects compressed air and utilities consumption — and emissions levels.

The industrial sector is responsible for 33% of total U.S. energy consumption, and it’s estimated that industrial manufacturers use more than 18.2 billion gallons of water from direct water withdrawals each day and about 12% of the public water supply. With today’s ambitious net-zero and water conservation goals, it’s in the best interest of the company and the environment to make decisions that optimize production and resource use.

Several factors influence the effectiveness of a company’s decision-making process to reliably improve sustainability. What informs decisions? How long do they take to make? Are they reactive, responding to an outcome after it’s happened, or are they proactive, taking action to bring about or prevent an outcome? A company’s ability to consistently make smart decisions that optimize resource use and reduce emissions while improving overall equipment effectiveness (OEE) often depends on the technology integrated throughout its floor.

The digital transformation of factory settings has equipped production lines with a variety of sensors that allow for continuous monitoring and provide data about compressed air, water, steam, gases, electricity and other critical utilities, as well as root cause analytics. By using this data and applying supervised and unsupervised machine learning algorithms, the generation and aggregation of data allow for not only descriptive and diagnostic analytics but the prediction of events like leakage and failures.

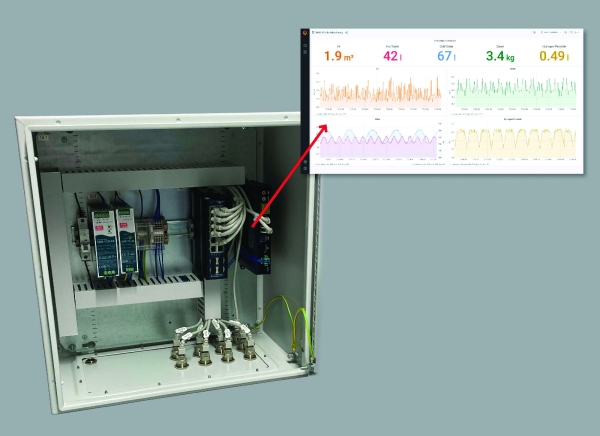

Image 1: Emerson’s multimedia monitoring solutions provide data about compressed air, water, steam, gases, electricity and other critical utilities leakages and translate it into valuable insights that can optimize productivity and prevent or reduce unplanned downtime. (image courtesy of Emerson). Click to enlarge.

Through a combination of continuous monitoring and machine learning, manufacturers can receive the insights and clarity necessary to make quick, informed decisions that can reliably optimize resource use and improve sustainability as well as productivity.

The Power of Prediction

Those familiar with digital transformation may be aware of the benefits that real-time monitoring and measurement provide, but predictive machine learning models may be new to them. While both models help provide valuable insights to inform decisions that can reduce costs and optimize processes, their results are of different degrees. Real-time monitoring informs users of an incident and enables them to react just after it happens. It minimizes the effects of an issue. Prediction models, on the other hand, can prevent issues altogether by providing information about what is going to happen. Instead of being notified shortly after the fact, end users receive information about an issue that will or may occur very soon. This empowers users to optimize their operations and move from reactive to proactive operational processes.

While monitoring solutions offer real-time insights, it’s fair to say that machine learning model predictions are future-time insights. We’ve seen from countless books and movies that knowing what will happen before it does happen is incredibly valuable. A plant that can precisely control operations informed by predictive machine learning models has the potential to achieve perpetual uptime, avoid quality issues and possibly prevent injuries.

In the ideally connected world, smart systems report failures before they happen and take the necessary corresponding actions. Imagine the process: the system predicts a leak and its location, then orders the component forecasted to fail and schedules maintenance in a regular time slot, all before a lot of air is lost. No unplanned downtime, no unnecessary energy consumption. Predictive machine learning models can make significantly optimized operations like this a reality.

Leading digital transformation solution providers are successfully developing accurate machine learning models for manufacturers to deploy. For example, engineers at Emerson have developed a machine learning-driven model that predicts the behavior of a pneumatics system. When minor deviations from the expected behavior occur, the model can detect the corresponding anomalies, such as leaks, and pinpoint their location within the system.

Compressed air production makes up 20% to 30% of overall energy costs across discrete and hybrid industries. However, a significant portion of this cost is unnecessary, since nearly a third to a fourth of industrial compressed air consumption is waste caused by leaks. At the same time, the growing complexity of industrial pneumatic systems can make it harder to identify the compromised subsegment or component where leaks occur. By accurately predicting the presence and location of such anomalies, machine learning models have the potential to prevent leaks altogether, reducing the amount of energy consumed — not to mention maintenance costs and unplanned downtime — and significantly improving overall system efficiency and sustainability.

How to Train a Machine Learning Model

The nature of typical industrial applications presents several challenges for a pneumatic learning model. Modern industrial machines and the environments where they operate can differ greatly. Temperatures and the dynamic viscosity of air itself change from plant to plant, preventing straightforward, linear models. The configuration and pneumatic architecture of each system vary from a few to several hundred components, and leaks are local events that models must assign to components.

In addition to this variation, many applications have a limited amount of training data available. Although the digital transformation of industrial equipment offers an extensive range of sensor and process data, little historical data exists because most machines have few, if any, sensors.

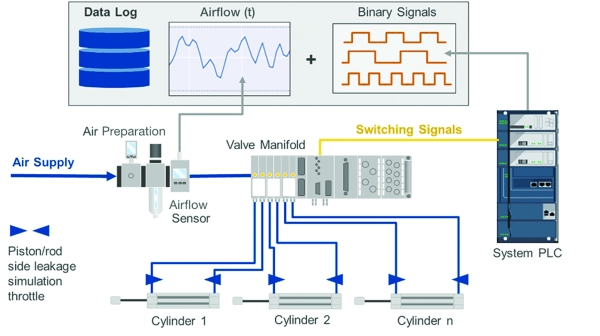

Luckily, the inclusion of even a few sensors provides enough reference behavior to train a machine model. It should be noted that this is basically the core mindset of digital transformation — most of the time, it’s not about inventing new algorithms or technology but instead understanding the environment and application and applying existing technological “bricks” that add value. For pneumatics, the most relevant data are the central flow rate of the compressed air and the binary control signals of the pneumatic valves, which are available in the control data from the system’s PLC.

What do the central flow rate and binary control signals tell a learning model about the presence or location of a leak? The flow rate itself doesn’t reveal anything except the general amount of consumed air. But it does provide a reference for the ideal workflow that the model should expect. That makes it critical that the central flow rate be measured with no actual or potential leaks present. When airflow deviates from this ideal workflow, it signals a potential leak. Correlating that deviation with the binary signals of the valve manifold will then indicate exactly where the anomaly occurs.

In Emerson’s application use case, this historical data is gathered by a smart sensor and a PLC. The sensor is integrated with an air preparation unit that supplies compressed air to the pneumatic system. As the compressed air moves through, the sensor measures the overall airflow of the system and stores historical data to a database. The system PLC switches the corresponding valves of a valve manifold that is connected to the piston and rod sides of a series of cylinders. The binary switching signals are then stored in the same database. (Images 2-3)

In addition to historical data, a successful dynamic airflow prediction model requires validation data. To create validation data, leakage is induced via a throttle at each input supply side of every cylinder. Thus, artificial leaks are generated and the corresponding data recorded helps to validate and improve the existing algorithms before applying the solutions to an existing field application.

Image 2: This diagram shows a typical, digitally transformed pneumatic system: an airflow sensor measures compressed air and stores collected data in a database, which sends signals to a PLC to switch corresponding valves on or off. (image courtesy of Emerson)

Image 3: Much more than a flow meter, the AVENTICS™ AF2 Flow Sensor continuously monitors compressed airflow, measures 8 performance parameters, including energy, and helps detect leaks in pneumatic systems. (image courtesy of Emerson)

The Real-World Value of Accurate Forecasting

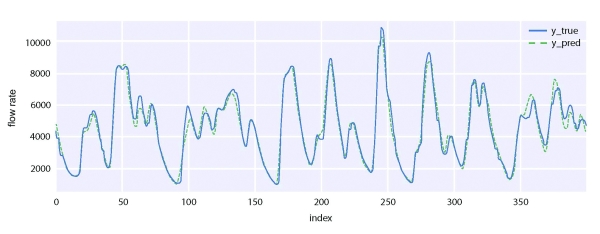

Meanwhile, models have successfully learned how to predict airflow in industrial pneumatic systems. For instance, Emerson’s machine learning model achieved a prediction accuracy of over 90%, forecasting significant anomalies and leakages, as well as indicating their location within the industrial machine. Even more, it determined a statistically significant forecast when creeping leakages affected the overall system behavior.

The system this model learned how to predict was an installed system without supervised learning or similar training data. The training data used included the overall airflow measurement without leakage, cross-correlated with the corresponding switching signals that made the system dynamics accessible. Based on the no-leakage data, the trained prediction model achieved an overall airflow prediction accuracy of the mean absolute percentage error of below 7%.

Image 4: Emerson’s IIoT engineers trained this prediction model, which achieved an overall airflow prediction accuracy of the mean absolute percentage error of below 7%. (image courtesy of Emerson). Click to enlarge.

While the prediction model for the airflow was the first step, the more complex, second step was to understand the behavior of the system using the corresponding valve switching signals to predict creeping leakage. Significant anomalies, like a broken pneumatics tube, are not very difficult to identify and locate because they usually make noise or stop the production process. A creeping leakage occurs rather silently and isn’t easily detected. These leaks can go unnoticed for long periods of time, subtly slowing cycle time, negatively impacting product quality and increasing energy costs. By identifying creeping leakage, machine learning models can help improve system efficiency in the long term.

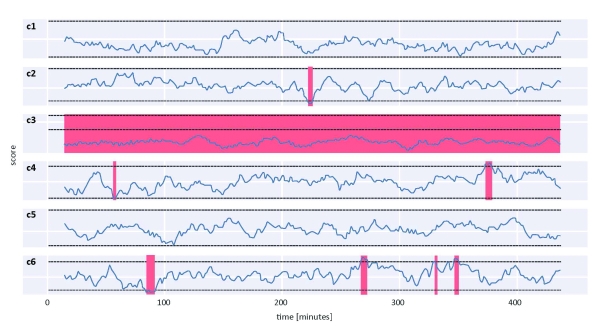

The airflow prediction model that was generated and continuously improved served as a reference of the pneumatics system, including the empirical null distribution of each cylinder side serving as the cylinder-specific reference score. If a leak occurred, the measured score would have a value that was bigger or smaller than the reference score. Using this deviation, the faulty cylinder or valve and corresponding piston or rod side of the component could be identified.

For significance testing, leakages were manually induced for the piston and rod sides of each cylinder. This graph shows that when leakage was induced at the piston input side of cylinder 3, the measured score value decreased and significantly deviated from the reference score. (Image 5)

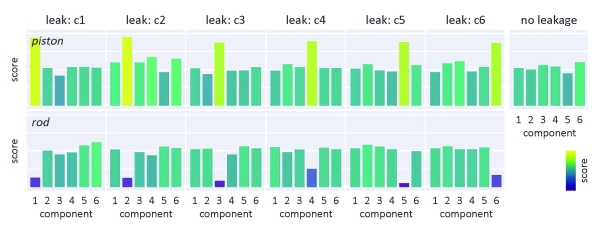

The full significance of the prediction model is demonstrated in this graph. (Image 6) Leakages were induced in 12 runs for each cylinder on both piston and rod sides, and the score values significantly deviated from the no-leakage reference data, pointing to the exact location of the induced leaks.

Image 5: This graph demonstrates how the score value decreased and differed from the reference score when leakage was induced at the piston input side of cylinder 3. (image courtesy of Emerson), Click to enlarge.

Image 6: In this 12-run example of a prediction model, it’s clear to see where leakages were induced on both piston and rod sides, as those leakage score values differ from the reference data. (image courtesy of Emerson). Click to enlarge.

Smarter Operations for a More Sustainable Future

AI-based condition monitoring and prediction can significantly improve a manufacturer’s decision-making process and optimize resource use and sustainability while improving OEE. And by reducing costs and increasing uptime, they can quickly pay for themselves.

As these sophisticated analytics tools become more and more accessible via standardized tool sets and libraries, organizations of all sizes can scale them for their sustainability goals and begin making decisions informed by what is really happening in their processes and machines in real — and future — time. By integrating machine learning models, their operations become proactive, not reactive, and manufacturers can achieve unprecedented control over their environmental impact today and tomorrow.

About the Authors

Dr. Michael Britzger is Senior Manager IIoT Engineering & Innovation Machine Automation at Emerson. In his role with his team, he focuses on data-driven software solutions and IIoT technology development for Emerson’s Digital Transformation initiative. Michael studied Economics and Physics in Austria, Spain and Germany. He earned a diploma from Leibniz University Hannover (Germany) and a doctorate degree (Ph.D.) in experimental gravitational physics from Albert Einstein Institute Hannover.

Dr. Michael Britzger, Senior Manager IIoT Engineering & Innovation Machine Automation, Emerson.

Nils Beckmann is Product Marketing Manager IIoT Integration for Fluid Control & Pneumatics at Emerson. In his role, he works in the IIoT environment, including the networking and analysis of machines and plants in the industrial environment. He has a master’s degree in applied software science.

Nils Beckmann, Product Marketing Manager IIoT Integration for Fluid Control & Pneumatics, Emerson.

About Emerson

Emerson is a global technology and engineering company providing innovative solutions for customers in industrial, commercial and residential markets. Emerson’s Automation Solutions business helps process, hybrid and discrete manufacturers maximize production, protect personnel and the environment while optimizing their energy and operating costs. Emerson’s Commercial & Residential Solutions business helps ensure human comfort and health, protect food quality and safety, advance energy efficiency and create sustainable infrastructure. For more information, visit www.emerson.com.

To read similar Pneumatics and Instrument Technology articles, please visit https://www.airbestpractices.com/technology/instrumentation

Visit our Webinar Archives to listen to expert presentations on Compressed Air Measurement and Monitoring at https://www.airbestpractices.com/webinars.