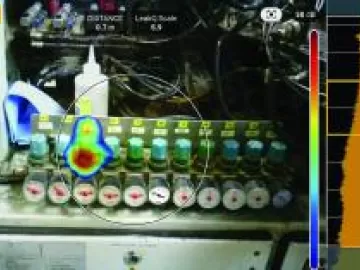

A High-Tech Way to Extend Your Reach to Leaks

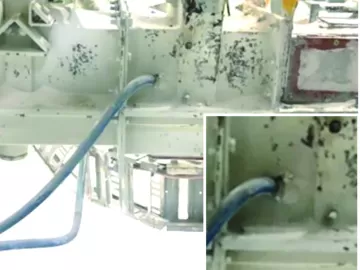

One of the best ways to reduce compressed air costs is to look for ways to reduce leakage flow, an unnecessary load that is a constant demand on the compressed air system. This flow is never-ending and occurs during production periods, and during quiet times at night or on weekends. Reducing the flow in a well-controlled compressed air system will result in the reduction of compressor energy consumption, usually by about \$1,750 per every 10 cfm, and often reduces pressure loss, allowing your machines to run better. This article discusses some recent experiences in using an acoustical imaging leak detector.