Safe and Efficient Compressed Air Nozzle Food Applications

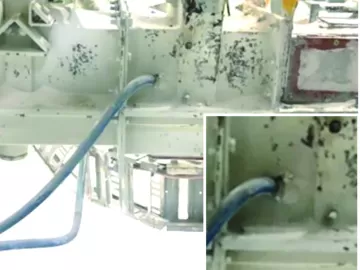

There are a tremendous variety of unique and creative ways people in the food industry have overcome their need for compressed air blowoffs used for cleaning, drying, cooling, conveying and overall processing. You may have seen some of them yourself. It is not uncommon to view open copper tubes, pipes with a crushed end, plugs or caps with holes drilled into them, modular flex coolant lines or nozzles designed for liquid application but blowing air.