With many (food and drink) processors running their production 24/7, compressor equipment needs to provide optimal reliability and performance, with minimal downtime. It is essential that the right lubrication is applied.

Compressed air is a key energy source, trusted across the food and beverage industry for all aspects of production and processing – from transport and processing of raw materials through to the final stages of packaging and bottling. Clean and contaminant-free compressed air is vital.

Growing awareness of the importance of food grade lubricants for consumer safety and Hazard Analysis and Critical Control Point (HACCP) regulations, as well as increasing consciousness about Kosher and Halal registrations triggered an increasing demand for high performance food grade lubricants.

With so many different lubricants to choose from, selecting an appropriate lubricant for your compressor that boasts the specific properties can be difficult. The right solution means considering consumer safety and enhanced performance, while also helping to reduce maintenance costs and downtime.

Standard mineral oil is unable to meet the greater demands that are now being placed on air compressor lubricants. Semi-synthetic and fully synthetic lubricants have excellent thermal oxidation stability, allowing for long machinery service intervals, and are able to cope with additional oil ageing caused by increased oil temperatures and downsized oil volumes.

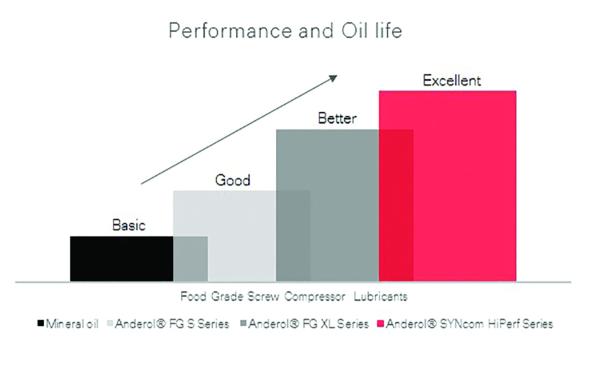

The following offers a Good, Better, and Excellent guide to selecting the most appropriate food grade compressor lubricant for your equipment:

Good: Semi-Synthetic Lubricants

Semi-synthetic food grade oils offer an attractive blend of low cost and good performance. These are formulated from synergistic blends of severely hydrotreated, hydrocracked (Group III) base oils to provide a more refined, high-quality product.

They are enhanced with premium synthetic esters and proven additive technology, which help to improve viscosity, wear resistance at higher temperatures, and stress levels, as well as increasing their detergency properties – resulting in clean machinery lubrication. Semi-synthetic oils can easily last up to 4,000 hours, twice as long as the 2,000 hours achieved by standard mineral oils.

Semi-synthetic lubricants offer some of the most desirable characteristics of a premium synthetic lubricant at a significantly lower cost. This makes it an economically attractive choice for customers looking to take advantage of the benefits of synthetic oils over mineral oils without additional costs.

The Anderol® FG S lubricant series is a good example of a compatible semi-synthetic and there is no need for special precautions when switching from a mineral oil-based lubricant for use with paints, seals, gaskets and hoses.

Better: PAO Based Synthetic Lubricants

Synthetic lubricants offer excellent levels of performance and have many advantages over mineral oil lubricants. Rotary screw compressors, in particular, require a synthetic lubricant.

Polyalphaolefin (PAO) based lubricants are most suitable for compressors and they offer a series of advantages such as high temperature thermal and oxidative stability, high flash point and low volatility, as well as being hydrolytically stable.

At Anderol we offer the Anderol® FG XL Series which is a high performance synthetic food grade lubricant with improved detergency for compressors and vacuum pumps. Its nominal operating range is -40°C to 170°C and the performance time is up to 8,000 hours.

Excellent: PAO/Ester Based Synthetic LUBRICANTS

Companies are increasingly balancing efficiency and sustainability. Machine operators expect longer machinery service intervals and therefore longer-life compressor lubricants. Longer oil life properties result in simply fewer production stops, a higher production output, less oil consumption and reduced waste.

PAO/ester based lubricant offers the best of a PAO base, enhanced with a special ester to take additive solubility and the detergency of the whole formulation to a completely different level. This results in very low deposits and cleaner machinery which improves the lubricant’s longevity and machine life.

For example, Anderol® SYNcom FG HiPerf 46 offers excellent viscosity to temperature behavior, has a wide operating temperature range (-40°C to 240°C), very low evaporation loss (<0.01% @100°C) of 22hrs according to ASTM D 972, and a very good film strength. This oil can last an entire maintenance cycle.

Extreme Environments

Very humid and acid environments require a special lubricant that does not hydrolyze at high temperatures, form sludge, or attack the seals and paints.

To meet these requirements, Anderol B.V. has developed C-NRT FGC for compressors and C-NRT Plus FG for vacuum pumps, which are inert to the reactive gases found in the more challenging compressor and vacuum environments. Anderol® C-NRT lubricants are full cyclic aromatics or mixed with a synthetic hydrocarbon base specially formulated to increase service life in aggressive environments.

Not only will this product withstand attacks of aggressive gasses and resist rapid breakdown, it is also capable of keeping the deposits in solution which has not been seen with any other mineral/ester/PAO based product in these circumstances. The thermal and oxidative stability of the base fluid together with oxidation inhibitors, extends the lubricant life at elevated temperature conditions.

Inert products do not degrade at the same speed as other lubricants in harsh conditions, thereby dramatically increasing the service life of the compressor or pump. They are specifically designed to provide inertness and long-term lubrication in applications, where contact with (reactive) chemistries cannot be avoided. Thanks to its excellent detergency effect deposit/lacquering formation is avoided.

Delivering Cost Savings

Synthetic high-performance compressor lubricants offer significant savings. Although the cost of synthetic lubricants may be higher, their benefits offset the initial outlay to offer an excellent return on investment.

Oil and filter replacement is minimized, disposal costs are reduced, and less maintenance brings down expensive labor costs. In addition, they improve machinery protection, reducing production stops and downtime and increasing productivity and output.

About Anderol B.V.

Anderol® is a specialty lubricants product line and brand within the Lubricant Additives Business Unit (LAB) from LANXESS. Anderol B.V., the European producer of Anderol® products, is a wholly owned subsidiary of specialty chemicals company LANXESS. All Anderol® Food Grade Compressor lubricants are NSF H1 Registered, produced in an ISO 21469 certified plant and Kosher and Halal certified. Anderol B.V. has a proven track record and over 80 years of experience specializing in compressor and food grade lubricants. Find out more about our food grade lubricants and our customized solutions at https://anderol.com.

This information and our technical advice – whether verbal, in writing or by way of trials – is subject to change without notice and given in good faith but without warranty or guarantee, express or implied, and this also applies where proprietary rights of third parties are involved. Our advice does not release you from the obligation to verify the information currently provided - especially that contained in our safety data and technical information sheets - and to test our products as to their suitability for the intended processes and uses. The application, use and processing of our products and the products manufactured by you on the basis of our technical advice are beyond our control and, therefore, entirely your own responsibility. Our products are sold in accordance with the current version of our General Conditions of Sale and Delivery.

©2022 LANXESS. Anderol®, LANXESS and the LANXESS Logo are trademarks of LANXESS Deutschland GmbH or its affiliates. All trademarks are registered in many countries in the world.

To read similar Air Compressor Lubrication Technology articles, visit https://www.airbestpractices.com/technology/air-compressors.

For expert presentations, visit our Webinar Archive Section dedicated to Air Compressor Technology at https://www.airbestpractices.com/magazine/webinars.