Actions speak more loudly than words. Growing up in Kansas, with wheat fields as your neighbor, we were taught to make observations like, “he’s a talker”, or “he’s the fancy-dressed guy”. Raw, sometimes menacing, and always waiting to get to the point, we were taught, “If you can’t back-up what you’re saying, don’t say anything.” These comments reflected a core Midwestern value – one that values substance. Substance is not a universally held trait and that holds true when firms claim to be good corporate citizens.

Atlas Copco AB is a Stockholm-based multinational corporation primarily focused on technologies used in compressed air and gas systems, generators, and construction and mining equipment. At the end of 2010, the Group employed 33,000 people with revenues of 7.3 Billion Euros. In my role as a journalist and market observer, substance in sustainability is a value I see “backed-up” at Atlas Copco - in terms of measurable metrics and innovative product development.

|

|||

Atlas Copco President and CEO, Ronnie Leten, leads ambitious sustainability goals for the 2010-2020 period |

Substance in the Sustainability Metrics

I was trained to be a business executive and, at the end of the quarter, measurable metrics defined the substance of one’s actions. The emergence of Sustainability, Energy Efficiency, and Corporate Responsibility as issues of interest to the consumer has created a buzz-saw of marketing activities and “fancy-dressed brochures”. Countless Corporate Citizenship Reports reside on web sites and are filled with images of green trees and blue lagoons. If you want to skip the fancy-talk, however, look to find a companies’ metrics on Sustainability and ask them how they report them.

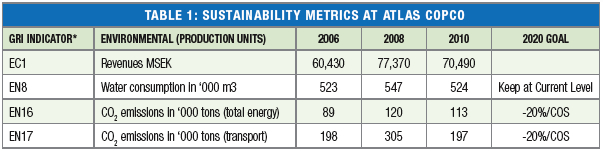

Karin Holmquist manages Corporate Responsibility for Atlas Copco. “In 2000, when we decided to start reporting metrics on sustainability, we found the Global Reporting Initiative (GRI) and implemented their Sustainability Reporting Guidelines in 2001.” Focused on advancing Corporate Responsibility and Transparency, GRI provides guidance on how organizations can disclose their sustainability performance. GRI is supported by the United Nations Global Compact (UNGC), the United Nations Environment Programme (UNEP), and the Organization for Economic Cooperation and Development (OECD).

Now on Version 3 of their Reporting Guidelines, one of the great benefits I observe about GRI is that it provides a platform for best practice sustainability reporting. Ms. Holmquist commented, “GRI has three transparency levels – Levels A, B, and C. In 2006, Atlas Copco went to the highest level, Level A transparency reporting on all core indicators.”

The 2010 Atlas Copco Annual Report and Sustainability Report integrates financial metrics with GRI sustainability metrics. They enable the understanding of how much energy is used in relation to sales activity. This permits the establishment of Energy Intensity metrics that all can manage to. Ms. Holmquist described the management structure involved, “Direct energy consumption is managed and decided on the company/divisional level. The Atlas Copco companies have assigned the task to environmental managers or Integrated Management System managers who support the work with continual improvements in the ISO 14001 management systems. There is a Group Safety, Health and Environmental (SHE) Council with representatives from business areas and corporate functions where SHE related issues are discussed. Recommendations from the SHE Council are decided by Group Management and implemented by operations.”

Atlas Copco President and CEO, Ronnie Leten, outlined ambitious sustainability goals for the 2010 - 2020 time period in his letter contained in the 2010 Atlas Copco Annual Report. The first commitment is that operations will keep water consumption at current levels – regardless of production levels. The second big one is that CO2 emissions per cost of sales (an Energy Intensity measure) will be reduced by 20 percent by the year 2020. The third significant commitment is that the technologies and services provided by the company will increase in energy efficiency by 20 percent by the year 2020.

- Operations will decrease CO2 emissions from operations and transport of goods by 20% in relation to cost of sales by 2020 vs. the base year of 2010

- Operations will keep water consumption at current levels

- Products/services/and solutions will increase the energy efficiency of products sold by 20% by 2020 vs. the base year of 2010

There is significant substance in the quality of the reporting of the metrics and in the goals set forth by Atlas Copco. The next time one of your suppliers tells you that they are a good Corporate Citizen, ask them what metrics they can supply on sustainability and how they come by their measurements.

* From page 120 of the 2010 Atlas Copco Annual Report.

Substance in Product Innovations for Sustainability

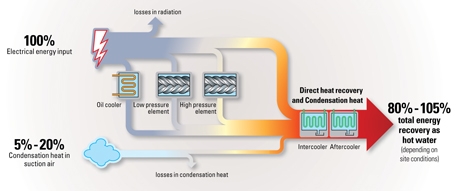

Product innovation in air compressor, as it relates to energy efficiency, is important due to a percentage of energy losses inherent to air compressor technology. A percentage of energy is lost, as waste heat, through radiation in the compression process. Holmquist commented, “This is why a key sustainability metric is to increase the energy efficiency of products sold by 20% by the year 2020.”

Heat recovery represents a significant energy-saving opportunity for compressed air users as a significant percentage (up to 94 percent) of the thermal energy can be recovered. Atlas Copco has introduced heat recovery packages, matching their air compressors, designed to provide low-grade heat to heat air or water to 140 F (90 C).

Thermal energy, captured from air compressors as a heat recovery project, can provide low-grade heat for industrial uses.

Sanjay Safaya and Conrad Latham next to the new, multi-compressor heat recovery packages

Atlas Copco introduced, in 2011 at the Hannover Fair, the new ZH 350+ oil-free, high-speed drive centrifugal air compressor. The company says it’s the first three-stage centrifugal air compressor with high-speed motors and without a gearbox. According to company product literature, the ZH 350+ is 4 percent more efficient than the company’s top-performing oil-free air compressors due to five design characteristics.

- The three-stage turbo design is widely recognized as the most efficient design for achieving compression between 7 and 11 bar.

- Elimination of the gearbox and thereby the transmission losses capable of resulting in a reduction of energy efficiency of up to 9 percent in compressors in the 350 kW range.

- Titanium impellers permit faster load-unload cycles. The gain in speed results in reduced power losses during low-demand periods.

- Optimally sized coolers reduce pressure drop

- The system blows off before the aftercooler meaning that minimal compressed air is lost when demand decreases.

The new oil-free, centrifugal, three-stage ZH 350+ air compressor

Another new product, introduced in 2011, will improve energy efficiency for food, electronics and pharmaceutical industries requiring -40 F (-40 C) pressure dewpoints. The ND Series heat of compression rotary drum dryer can now provide this dewpoint level while consuming virtually no energy. In the past, these customers typically purchased desiccant air dryers with up to 15% compressed air purge losses.

The new ND heat of compression rotary drum dryer provides a -40 F dewpoint with virtually no energy cost.

Other product innovations, introduced in 2011, include variable speed blowers designed for partial load applications (like wastewater treatment plants). The wastewater industry is realizing their aeration processes are not fixed-speed applications. A new nitrogen generator allows plants to self-generate nitrogen and reduce the sustainability footprint associated with the transport and delivery of nitrogen to their facilities. With these products, Atlas Copco is off to a fast start in achieving the 20% improvement in energy efficiency metric.

Conclusion

As a publisher and journalist, I observe a lot of “green-washing” from firms claiming energy efficiency and sustainability. Substance behind claims is not always to be found. Atlas Copco has demonstrated significant substance in sustainability claims in both how they report their performance and in the products brought to market.