Introduction

The Compressed Air and Gas Institute is the united voice of the compressed air industry, serving as the unbiased authority on technical, educational, promotional, and other matters that affect the industry. Mention utilities and energy in a discussion about manufacturing and the Big Three - water, electricity and natural gas - immediately come to mind. But compressed air is commonly accepted as a manufacturing facility's fourth utility. A careful examination of a facility's compressed air system will likely reveal several opportunities to improve the performance of the compressed air system by effectively and efficiently removing moisture from the compressed air system. The Compressed Air and Gas Institute (CAGI) committed to issuing a series of articles discussing moisture in the compressed air system. The first article covered “Why Do Compressed Air Systems Need Drying?” This article will provide a brief overview of the two most popular compressed air drying technologies available – Refrigerant Type and Regenerative Desiccant Type.

The Compressed Air and Gas Institute is the united voice of the compressed air industry, serving as the unbiased authority on technical, educational, promotional, and other matters that affect the industry. Mention utilities and energy in a discussion about manufacturing and the Big Three - water, electricity and natural gas - immediately come to mind. But compressed air is commonly accepted as a manufacturing facility's fourth utility. A careful examination of a facility's compressed air system will likely reveal several opportunities to improve the performance of the compressed air system by effectively and efficiently removing moisture from the compressed air system. The Compressed Air and Gas Institute (CAGI) committed to issuing a series of articles discussing moisture in the compressed air system. The first article covered “Why Do Compressed Air Systems Need Drying?” This article will provide a brief overview of the two most popular compressed air drying technologies available – Refrigerant Type and Regenerative Desiccant Type.

Compressed Air Dryer Selection

Different methods can be used to remove the moisture content of compressed air. Current compressed air dryer types include the following products:

- Refrigerant type:

- Cycling

- Non-cycling

- Regenerative desiccant type:

- Heatless (no internal or external heaters)

- Heated (internal or external heaters)

- Heat of Compression

- Single Tower

- Deliquescent

- Desiccant

- Membrane

Because of such a wide breadth of product offering, we will cover each of these dryer types in some detail. It is always recommended that the compressed air treatment products be discussed in concert with the entire compressed air system and the application of the products. You should consult a compressed air expert to assure that the compressed air dryer selected is correct for your application.

|

A Refrigerant Type Compressed Air Dryer |

Refrigerant Type Dryers

Although it does not offer as low a dew point as can be obtained with other types, the refrigerant type dryer has been the most popular, as the dew point obtained is acceptable in many general industrial plant air applications. The principle of operation is similar to a domestic refrigerator or home air conditioning system. The compressed air is cooled in an air-to-refrigerant heat exchanger to about 35°F, at which point the condensed moisture is separated and drained off. The air is then reheated in an air-to-air heat exchanger by means of the incoming air, which also is pre-cooled before entering the air-to-refrigerant heat exchanger. This means that the compressed air leaving the dryer has a pressure dew point of 35 to 40°F. A lower dew point is not feasible in this type of dryer as the condensate would freeze at 32°F or lower.

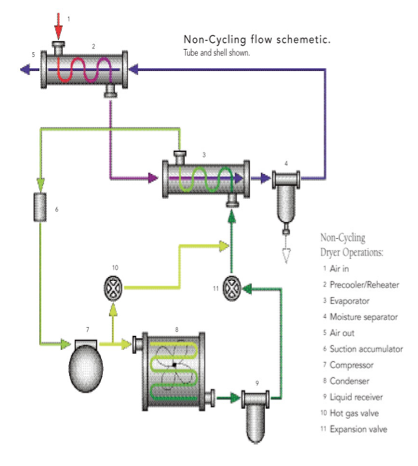

In a non-cycling refrigerant dryer (see below), the refrigerant circulates continuously through the system. This design provides rapid response to changes in operating loads. Since the flow of compressed air will vary and ambient temperatures also vary, a hot gas bypass valve or unloader valve often is used to regulate the flow of the refrigerant and maintain stable operating conditions within the refrigerant system. In most designs, the refrigerant evaporates within the air-to-refrigerant heat exchanger (evaporator) and is condensed after compression by an air-or water-to-refrigerant heat exchanger (condenser).

Non-cycling Refrigerant Dryer Diagram

While older refrigerant type air dryers have used CFC refrigerants such as R12 and R22, newer designs are in compliance with the Montreal Protocol and use chlorine free refrigerants such as R134A and R407C or other environmentally friendly refrigerant blends. The properties of these newer refrigerants require careful attention to the refrigeration system design, due to differences in operating pressures and temperatures. Refrigerant type dryers should only be serviced by a licensed and trained technician to assure that the refrigerant material is properly handled.

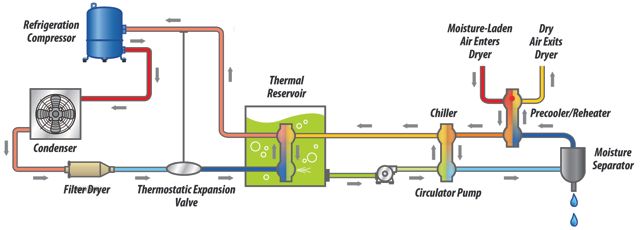

Cycling type refrigerant dryers use refrigerant to chill a mass surrounding the air passage in the heat exchanger. This mass may be a liquid such as glycol or a metal such as aluminum block, beads or related substance, which act as a heat sink. The compressed air is cooled by the heat sink which has its temperature controlled by a thermostat and shuts off the refrigerant compressor during reduced loads, providing savings in operating costs but at higher initial capital cost.

Advantages of Refrigerant Type Air Dryers include:

- Low, initial capital cost.

- Relatively low operating cost.

- Low maintenance costs.

- Not damaged by oil in the air stream (although, filtration normally is sometimes recommended).

Disadvantages of Refrigerant Type Air Dryers include:

- Limited dew point capability.

Advantages of non-cycling designs include:

- Minimal dew point swings

- Refrigerant compressor operates continuously

Disadvantages of non-cycling designs include:

- No energy savings at partial and zero air flow

Advantages of cycling designs include:

- Energy savings at partial and zero air flow.

Disadvantages of cycling designs include:

- Dew point swings

- Increased size and weight to accommodate the heat sink mass

- Increased capital cost

Desiccant Heatless Dryer Schematic

Heat of Compression Desiccant Dryer Basic Principles - Webinar RecordingDownload the slides and watch the recording of the FREE webcast to learn:

|

Regenerative Desiccant Type Dryers

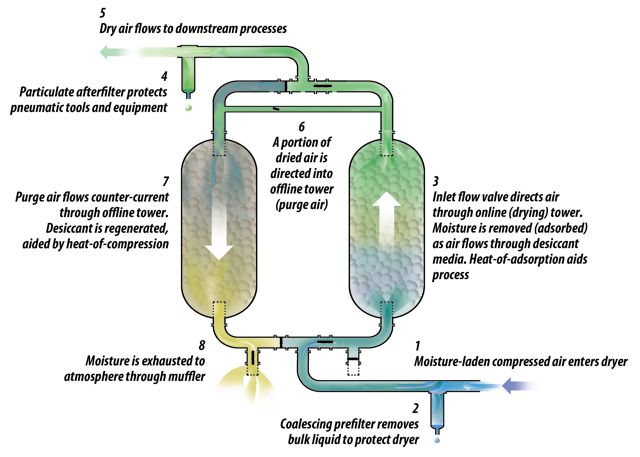

These dryers use a desiccant, which adsorbs the water vapor in the air stream. A distinction needs to be made between adsorb and absorb. Adsorb means that the moisture adheres to the desiccant, collecting in the thousands of small pores within each desiccant bead. The composition of the desiccant is not changed, and the moisture can be driven off in a regeneration process by applying dry purge air, by the application of heat, or a combination of both. Absorb means the material that attracts the moisture is dissolved in and used up by the moisture. Absorption takes place in a deliquescent desiccant type dryer.

Regenerative desiccant dryers normally are of twin tower construction. One tower dries the air from the compressor while the desiccant in the other tower is being regenerated after the pressure in the tower has been reduced to atmospheric pressure. Regeneration can be accomplished using a time cycle or on demand by measuring the temperature or humidity in the desiccant towers or by measuring the dew point of the air leaving the on-line tower.

In the heatless regenerative desiccant type, no internal or external heaters are used. Purge air requirement can range up to 18% of the total air-flow. The typical regenerative desiccant dryer at 100 psig has a pressure dew point rating of -40°F but dew points down to -100°F can be obtained.

Heat reactivated regenerative desiccant dryers may have internal or external heat applied by heaters. In the internal type, steam or electricity may be used in heaters embedded in the desiccant bed. This reduces the amount of purge air required for regeneration to less than 10%. The purge air plus normal radiation is used to cool the desiccant bed after regeneration to prevent elevated air temperatures going downstream.

In externally heated regenerative desiccant dryers, the purge air is heated to an elevated temperature and then passes through the desiccant bed. The amount of purge air is approximately 5-10% of the air flow through the dryer. The purge air from the compressed air system can be eliminated if a blower is used for the circulation of heated atmospheric air through the desiccant bed. To protect the desiccant bed from oil contamination from the air compressor, a coalescing filter is required upstream of the dryer. To protect downstream equipment from desiccant dust or “fines”, a particulate filter downstream of the dryer also is also recommended.

Advantages of Regenerative Desiccant Type Dryers include:

- Very low dew points can be achieved without potential freeze-up.

- Moderate cost of operation for the dew points achieved.

- Heatless type can be designed to operate pneumatically for remote, mobile or hazardous locations.

Compressed Air Purification & Piping Monthly e-NewsletterWith a focus on Demand-Side Optimization, compressed air dryers, filters, condensate management, tanks, piping and pneumatic technologies are profiled. How to ensure system reliability, while reducing pressure drop and demand, is explored through System Assessment case studies. |

Disadvantages of Regenerative Desiccant Type Dryers include:

- Relatively high initial capital cost

- Periodic replacement of the desiccant bed (typically 3-5 years)

- Oil aerosols can coat the desiccant material, rendering it useless if adequate pre-filtering is not maintained.

- Purge air usually is required.

Refrigerant Cycling Dryer Schematic

The next article in the series covers the other Regenerative Desiccant Dryer Type: "Heat of Compression". It will also address Single Tower Types, as well as Membrane Dryers. Read.

The CAGI website is an excellent source for more information on the application of compressed air dryers, compressed air dryer and filtration selection, and information on the Air Dryer & Filtration Section.

For more detailed information about CAGI, its members, compressed air applications or answers to any of your compressed air questions, please contact the Compressed Air and Gas Institute. CAGI educational resources include e-learning coursework on the SmartSite, selection guides, videos and as well as mentioned Compressed Air & Gas Handbook.

To read more Air Treatment Technology articles, visit www.airbestpractices.com/technology/air-treatment.