Introduction

It is widely recognized that compressed air systems account for ten percent of all electricity and roughly sixteen percent of U.S. industrial motor system energy use. Seventy percent of all manufacturing facilities in the United States use compressed air to drive a variety of process equipment. (1)

There are many ways that compressed air users can reduce their energy costs through air audits and eliminating wasteful air consuming processes, which can lead to a 10 to 15% system energy reduction with simple paybacks in less than two years. (2)

System operators should also examine if a reduced system pressure could be used. Use of a central control system can more effectively stage the existing air compressors to cyclical demand. Increased storage capacity can also reduce the unnecessary high demand cycling of compressors.

This article is mainly directed at identifying and quantifying the potential for heat reclaim from the air compressors themselves. Both air-cooled and water-cooled air compressors can be used to provide cost savings in a manufacturing plant through the use of a properly designed and sized heat reclamation system.

Seven Key Sustainability Projects |

|

|---|---|

| 1. Metering | 5. Lighting |

| 2. Demand Control | 6. Heat Recovery |

| 3. HVAC Optimization | 7. Project Implementation |

| 4. Compressed Air | |

Calculating Reclaimable BTU’s

It is possible to reduce your plant's total “carbon footprint”, energy consumption, and reduce operating costs by recovering the excess heat air compressors produce.

The electric motor puts energy into the compressed air stream through the compression process. Motor power is typically rated in horsepower. One horsepower is the equivalent of 2,545 BTU per hour. Although most air compressors are sold in nominal horsepower sizes, they generally can operate at loads 10 percent above the motor nameplate rating to achieve rated compressor discharge pressure and full capacity output. The horsepower at the compressor shaft, also referred to as brake horsepower (bhp), can be 10 percent above motor nameplate horsepower and consume most of the motor's 1.15 service factor safely. Therefore, a 100-horsepower compressor (110 bhp) converts electricity into almost 280,000 BTU per hour at full load. In addition, the air-cooled motor itself, having an assumed efficiency of 93 percent dissipates an additional 19,600 BTU of heat per hour.

The air compressor increases the pressure and proportionately reduces the volume of the air. The energy potential of the original entering air is now at a much higher level due to the increased pressure, ready to do work downstream in the compressed air system. It is possible to extract, by heat transfer, as much as 80-90% of the energy that the electric motor placed into the compressed air. Heat must be removed to maintain the compressor tolerances and clearances, and the compressed air usually must be cooled to make it suitable for most processes. The compressed air still contains energy to do useful work even after the excess heat has been removed.

Heat and work are two different methods of transferring energy. After the compression process increases the air pressure and raises its temperature, the amount of energy not used as work, the excess heat of compression is now available for reuse. Unfortunately most facilities now “dump” this excess heat outside when they could be reusing it and reducing operating costs. The most common uses for the recovered energy include industrial process heating, supplemental space heating, makeup air heating, domestic or process hot water or preheating boiler make-up water.

Air-Cooled Air Compressors

Typically the heat-reclaim potential from an air-cooled compressor has been limited to supplemental space heating. When considering the use of air-cooled compressors, properly sized ductwork and the use of booster fans to direct the heat being reclaimed from a central compressor room to the needed location of the reclaimed heat can be a significant expense. Many times the air-cooled compressors are relegated to “boiler rooms” that do not have proper ventilation. These centralized compressors can experience elevated operating temperatures that reduce equipment life, increase maintenance and repair cost, and ultimately can yield an unreliable air system. The initial cost of a good ventilation system is usually far less than the ongoing increased maintenance costs of a hot operating environment. It's advisable to consult with HVAC experts to ensure proper ventilation and to evaluate possible heat recovery opportunities with air-cooled compressors.

The larger the air compressor system, the harder it is to reclaim a majority of the generated heat - due to the large air flows required. A 250 Bhp, air-cooled air compressor will generate about 636,000 Btu/Hr of heat. This will require about 15,000 cfm of air movement.

The compressor ventilating system design should also consider the additional effect on the rest of the plant's ventilating system, including heating, air conditioning, and possible negative and positive pressures that can affect the performance of the air compressor.

Water-Cooled Air Compressors

The heat reclaim potential from a water-cooled compressor has the flexibility to allow for varied forms of heat usage. There are two major types of water-cooled systems available; open-cooling loops and closed-cooling loops. Open-loop cooling is accomplished by using recirculating, open-loop, cooling tower water, or once-through well water or city water that then is discharged to the sewer or environment.

Once-Through Cooling Systems

Once-through cooling systems can be effective at raising the temperature of the incoming water from 50 °F to about 90 °F and can then be used for preheating boiler feed water, domestic, or process heated water. This water must eventually be discharged to a sanitary sewer or a permit for discharging to the environment must be obtained. Since the water is not treated, scale buildup from dissolved solids and potential corrosion of the air compressor heat exchanger must be factored into the life cycle maintenance costs of an air compressor system. The cost of discharging this water can be more expensive than the incoming cost of water due to the sewer fees, environmental testing and permits, and possible treatment required.

Recirculating Open-Loop Cooling Systems

Cooling towers are the most common form of this type of system. These systems utilize the principle of evaporation to cool the water to below-ambient, dry-bulb conditions. Most tower systems are designed to provide 85 °F cooling water in the United States based upon a 75 °F to 78 °F wet-bulb temperature.

Cooling towers are the most common form of this type of system. These systems utilize the principle of evaporation to cool the water to below-ambient, dry-bulb conditions. Most tower systems are designed to provide 85 °F cooling water in the United States based upon a 75 °F to 78 °F wet-bulb temperature.

A cooling tower will drastically reduce the amount of water consumption compared to a once-through system. They have, however, the requirement of additional water treatment costs to reduce the potential for:

- Scale from the higher concentration of dissolved solids in the cooling water

- Potential biological contamination of the cooling water from algae and bacteria

- Increased filtration of the cooling water from the atmospheric dirt and debris blown into the water from the tower fans.

Most cooling towers are designed for a 10 °F rise in temperature - but can be designed to go higher. The scale formation potential is increased as the temperature of the water goes up. Care must be used to make sure the hot water does not exceed the temperature rating of the PVC fill that is in most cooling towers to avoid decomposition of the fill.

Open-loop cooling water can be used for preheating boiler feed water, domestic, or process heated water. It might be used for space heating potential, but the typical lower inlet temperatures (95° F) produces a lower grade heated air from the cooling coil that is sometimes considered “too cool”. Also at these lower temperatures the surface area of the coil is larger to allow for proper heat extraction. Tower water should not be used to temper building makeup air because when the inlet ambient temperature is below freezing, there is a strong chance that freezing of the coils can occur.

Closed-Loop Recirculating Cooling System

There are four main types of closed-loop cooling systems that are available; dry type, dry type with trim cooler, evaporative type, and water-to-water heat exchanger systems.

The main advantage of all of these systems is that since they are closed-loop, you can almost eliminate water-caused maintenance issues with your compressors. Besides the initial expense of filling them with an ethylene or propylene glycol mixture with corrosion inhibitors, they require no ongoing water treatment except for checking the concentration yearly for your winter ambient air conditions and to verify the proper pH levels.

Since the compressor heat exchangers will remain virtually scale free, one can take a higher temperature differential across the compressors heat exchangers without loss of cooling to the equipment. Most compressors are designed to allow for a 25 °F to 30 °F rise in temperature across a clean heat exchanger. If a new closed-loop cooling system is retrofitted to an existing system that previously was on an open cooling water loop, the heat exchanger must be cleaned before placement on a new closed loop cooling system.

Closed-loop systems allow for better space heating potential because of the higher fluid temperatures returning from the load. These higher temperatures allow the discharge air from the heat reclaim coils to be typically in the high 90°F range. Again with a higher operating system temperature, the size of the cooling coil can be of a reduced size and still allow for proper cooling of the air compressor cooling fluid. Also since they will have the proper solution of glycol for protection from freezing in winter conditions, they could be used for preheating make-up air on a central air handler.

Closed-loop systems allow for better space heating potential because of the higher fluid temperatures returning from the load. These higher temperatures allow the discharge air from the heat reclaim coils to be typically in the high 90°F range. Again with a higher operating system temperature, the size of the cooling coil can be of a reduced size and still allow for proper cooling of the air compressor cooling fluid. Also since they will have the proper solution of glycol for protection from freezing in winter conditions, they could be used for preheating make-up air on a central air handler.

It is also easier to transport the hot fluid to distant locations in the plant, where the heat reclamation is most needed, through a piping system than through ductwork. If space heating in an area needs a more diffused distribution of hot air, numerous smaller air-to-water coils can be used rather than one large coil.

It is also easier to transport the hot fluid to distant locations in the plant, where the heat reclamation is most needed, through a piping system than through ductwork. If space heating in an area needs a more diffused distribution of hot air, numerous smaller air-to-water coils can be used rather than one large coil.

Please Note: A properly designed heat reclaim system does not reduce the size of the primary cooling system. If you are not utilizing the heat reclaim system for any reason, the primary cooling system must still be sized to reject the total heat load outdoors that is generated by the compressors.

Heat Reclaim Analysis

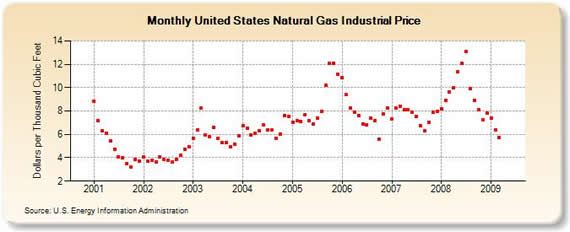

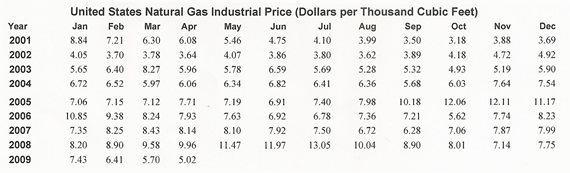

Let’s take a look at the dollar and cents of the heat reclaim potential available. Production of natural gas is described in terms of standard cubic feet, which is a measure of quantity of gas at 60 degrees Fahrenheit and 14.65 pounds per square inch of pressure. Similar to the convention used for oil, the term "mcf" means 1 thousand cubic feet of gas and "mmcf" means 1 million cubic feet of gas.

A "mmbtu" (1,000,000 btu) is roughly equivalent to 970 cubic feet of gas. Your gas bill may be priced on mcf or 1,000 cubic feet. Consumers frequently think of a mcf of gas as being equivalent to one mmbtu. It actually is mcf (1,000 Cubic Feet ) = 1,030,928 btu’s

Some gas bills are still priced in “therms” which is defined as 1 therm = 100,000 Btu

Natural gas market future prices are sold on the New York Mercantile Exchange and spot prices are typically set at the Henry Hub and are denominated in \$/mmbtu (one million British Thermal Units) and are generally seen to be the primary price set for the North American natural gas market. This pricing is the cost to the distribution companies, your pricing will be higher due to the transportation costs added on by the distribution companies. You should check you current billing statement for accurate data.

The Henry Hub is a point on the natural gas pipeline system in Erath, Louisiana. It is owned by Sabine Pipe Line LLC. It interconnects with nine interstate and four intrastate pipelines: Acadian, Columbia Gulf Transmission, Gulf South Pipeline, Bridgeline, NGPL, Sea Robin, Southern Natural Pipeline, Texas Gas Transmission, Transcontinental Pipeline, Trunkline Pipeline, Jefferson Island, and Sabine.

Oil production companies measure oil production in terms of barrels. A barrel, usually abbreviated as "bbl", is 42 U.S. gallons. A common methodology in the oil industry is to use a prefix of "m" to indicate 1,000 and a prefix of "mm" to indicate 1 million. Therefore, one thousand barrels is commonly denoted as "mbbl" and one million barrels is denoted as "mmbbl".

If you are using oil to fuel your boiler, we can convert the oil usage into a gas energy equivalent basis using barrels of oil equivalent ( BOE). One BOE has the energy equivalent of 6,040 cubic feet of gas – or 6.04 mcf X 1,030,928 btu/mcf = 6,226,805 btu per barrel of oil usage. The US Internal Revenue Service defines it as equal to 5.8 × 106 BTU (5,800,000 btu’s)

Your results should be based upon your actual heat load, your local cost for natural gas, and the best estimate you have on your operating conditions, (how many weeks per year and hrs/day/week ). The example is for your reference and guidance only.

Example

Let us assume that we have a 400 hp, water-cooled, air compressor that will generate 1,018,000 btu/hr. We can save energy by either;

- Utilizing the hot water coming off of the air compressor to provide space heating and shutting off gas-fired space heaters

- Preheating boiler feed water

- Preheating makeup domestic or process hot water coming in from the city water supply.

Let us also assume that we have a very efficient burner on either the space heater or boiler at 80% efficiency. Most new high efficiency burners approach this figure while existing older units might be in the 60% range.

Current natural gas wellhead futures pricing (September delivery 2009) = \$3.58/mmBtu (not including distribution costs). Typical industrial natural gas pricing including distribution cost is usually about \$2.00 more per mmBtu. Current natural gas prices are at a seven year low.

This example shows savings for space heating. Potentially if you are preheating water, you might be able to save energy every hour that your plant is operating. If we were able to recycle 1,018,000 Btu/hr for 4032 hours per year (assuming ambient air temperature at 70°F or lower), we would save 4,104 mmBtu/yr.

If we reduced heating by natural gas at a 80% burner efficiency, 5,130 mmBtu/yr input gas energy would be required to generate the 4,104mmBtu/yr heating output volume being saved. Multiply 5,130mmBtu/yr by \$5.58/mmBtu and the savings equal \$28,625 per year.

CO2 Reduction Potential

If you are interested in reducing your carbon footprint, using the same example as above, this would also reduce your CO2 emissions by about 5,130mmBtu/yr X 113 lb CO2/mmBtu = 579,690 lbs CO2/yr. Again these calculations are for a 400 hp compressor. For a 100 hp compressor one could realize a \$7,156 savings per year and 144,922 lb CO2 reduction.

As one can see there are compelling reasons to consider integrating a heat reclamation system either into a new installation or retrofitting an existing system. System payback is quite varied depending on the operating schedule of the facility, climatic conditions, and the potential use of the reclaimed heat. An additional life cycle consideration should be the reduction of maintenance and the potential longer air compressor life cycle that can be accomplished with a properly designed cooling system.

If you are considering using what is otherwise discarded heat from your compressors you should contact a cooling professional to help you evaluate your system. Heat recovery and “going green” is on everyone’s hot list. It needs to be done correctly, however, to provide the proper estimated payback.

For more information, please contact HydroThrift Corporation at email: sales@hydrothrift.com, tel: 330-837-5141, www.hydrothrift.com.

Bibliography:

(1) Assessment of the Market for Compressed Air Efficiency Services; Office of the Energy Efficiency and Renewable Energy;

U.S. Department of Energy; June 2001. DOE/GO-102001-1197

Also XENERGY, Inc (1998) United States Industrial Electric Motor Systems Market Opportunities Assessment. Washington D.C.; U.S. Department of Energy, Office of Industrial Technologies, and Oak Ridge National Laboratory

(2) XENERGY, Inc (1998) United States Industrial Electric Motor Systems Market Opportunities Assessment. Washington D.C.; U.S. Department of Energy, Office of Industrial Technologies, and Oak Ridge National Laboratory