Improve Process Efficiency and Reduce Energy Use with Compressed Air Monitoring

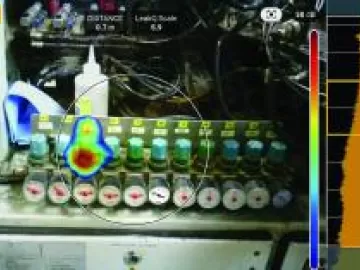

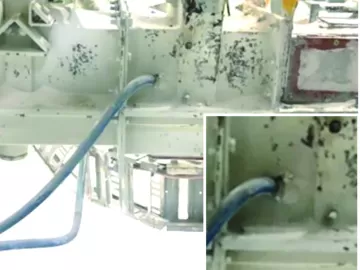

Without compressed air monitoring, up to 30% of the compressed air generated goes to waste. This waste occurs for several reasons, including leaks caused by failures at joints and tubes, exposure to vibration and normal component wear, and the suboptimization of machines and devices. Continuous monitoring capabilities allow operators to detect leaks and other anomalies in their early stages. By addressing pneumatic issues before they can grow, companies can reduce compressed air use by 20% to 30%.