When Hitachi Industrial Equipment Systems Co., Ltd. (HIES) announced Sullair, Hitachi, and Champion Compressors (Australia) have come together under the umbrella of Hitachi Global Air Power (HGAP), many wondered what it would all mean.

It means good things are in store for HGAP and its customers, said Yasuhiro (Charlie) Takeuchi, President & Director of HIES, and John Randall, President & CEO of HGAP. Both shared insights into the establishment of HGAP as a unified global compressed air business. David Andrews, HGAP Vice President of Global Marketing & Communications, also provided views on the company announcement.

Company leaders said the formation of HGAP puts the organization in a strong position to deliver compressed air solutions that meet the demands of customers with diverse applications throughout the world. Customers can also expect to see a range of innovations introduced in the months and years ahead that will help them improve sustainability, growth, and profitability, thanks to HGAP’s heavy emphasis on idea sharing and strategic planning – all of which builds on more than 100 years of technological advancements.

Hitachi has invested $45 million in Hitachi Global Air Power’s Michigan City, Indiana, manufacturing facility since 2017. John Randall next to new airends from the new machining centers.

Broader Resources Support Established Brands

While the creation of HGAP makes for a strong global company, Takeuchi and Randall said the organization remains unchanged in terms of ownership, leadership, and staff. HGAP will also continue to market and support products and solutions as distinct Sullair, Hitachi and Champion Compressors brands.

The company will be managed globally by Randall as before when he served as President & CEO of Sullair, located in Michigan City, Indiana. Sullair became a wholly owned subsidiary of Hitachi, Ltd. in 2017. Randall was named Sullair’s leader in 2021. Takeuchi, who joined Hitachi in 1991, was instrumental in the creation of HGAP. His years of leadership experience with Hitachi’s compressed air side of the business includes serving as CEO of Sullair in 2020.

|

|

Yasuhiro (Charlie) Takeuchi, President & Director, Hitachi Industrial Equipment Systems Co., Ltd. |

John Randall, President and CEO of Hitachi Global Air Power. |

Takeuchi said HGAP represents a mixture of the entire company’s best manufacturing technology, product technology and talent.

“We need to support our customers globally. It made sense to form Hitachi Global Air Power to bring our best strengths together and bring that to the customer,” he said. “Distributors will also continue to be very important for us as we continue to take care of our customers’ assets.”

Since acquiring Sullair in 2017, Hitachi has invested $45 million in the Michigan City operation to bolster its manufacturing capabilities. The investment, Takeuchi said, exemplifies HGAP’s commitment to deliver the best possible product and services to customers where they do business.

“We want to have a local presence and local capability to support our customers,” said Takeuchi. “It’s important we do what the customer wants us to do.”

The formation of HGAP, Randall said, is part of a strategic plan established long ago as HIES set out to integrate corporate resources over time.

“The brands will continue to remain strong,” he said, adding that HGAP is working through how best to integrate and utilize capabilities of the business at an organizational level.

“An example is the consolidation of global engineering under one leader to help our regionally based product management teams with a roadmap for satisfying customers’ needs in each market,” Randall said. “We’ll also look at how we manage operations globally to best utilize the strength of the total organization to satisfy customer needs around the world.”

Randall said sales team will also continue to evolve in terms of compressed air products and beyond.

“We’re already working with the global sales team at the Hitachi, Ltd. level to make sure we can serve customers from multiple different perspectives, not just at the air compressor level. If we can help other parts of Hitachi and vice versa we can not only satisfy the customer but grow with them as well,” he said.

Product Strategies Taking Shape

There are a variety of examples of how HGAP will capitalize on the concept of idea sharing and planning to strengthen its service offering. The process has already begun, said company leaders.

A prime example, Randall said, is the adaptation of a 50 Hertz (Hz), CE-compliant DS Series oil-free rotary screw air compressor manufactured in China and engineered for the European market. The machine, which was recently introduced at the Hanover Fair, Hanover, Germany,

is currently being adapted for the United States as a Sullair air compressor.

“That’s another strength of utilizing the entire engineering organization within Global Air Power,” Randall said. “We’ve basically taken that rock solid airend that Hitachi developed for that product range and did some things differently with things like serviceability, airflow, and size to make it more applicable in other markets.”

The big-picture idea, Randall said, is to develop a regional manufacturing strategy. The DS oil-free 50-Hz product is only one example.

“We launched that product in one location. As we start to see the volume build, we will localize it here in the United States to be closer in-market to the customer. We want to provide a complete solution with everything from the product to the technical support and service where our customers are,” he said, noting how plans call for manufacturing a full range of Sullair-branded oil free air compressors from 30 horsepower (hp) to 600 hp. Sullair currently offers stationary rotary screw air compressors from five hp to 600 hp and portable air compressors that generate from 185 to 3,000 cfm each.

HGAP will continue to invest in technologies that help customers improve efficiencies and achieve sustainability goals, Takeuchi said, adding Hitachi has a strong corporate commitment to sustainability. He said HGAP will continue to invest in key technologies such as motors, drives and airends.

“We want to support our customers and that means providing them with green products and solutions,” Takeuchi said.

Voice of Customer a Driving Force

While engineering and operational synergies are a major focus, the driving force in HGAP’s go-to-market strategy will continue to be the voice of the customer, said David Andrews, who previously served as Vice President, Global Marketing and Communications at Sullair.

An example is how HGAP took to heart the need for serviceability in the design of its LS Series rotary screw air compressors. Distributor and customer input led to improved lift-off panels for the lubricated air compressor line as an important feature, which will also be incorporated into the oil-free air compressors.

“Distributors and end users want easy to access serviceable components,” Andrews said, noting how understanding the customer contributes to overall product performance and reliability. “An efficient air compressor only runs efficiently if it’s being serviced.”

The oil-free line will also see the introduction of the Sullair touch-screen controller that has gained popularity with the LS Series product line. The controller can manage as many as 16 air compressors as part of a compressed air system.

The newly expanded Sullair LS Series industrial air compressors highlight the company’s focus on efficiency and ease of use.

“We’ve put a lot of thought into how we move forward with compatibility to be able to make it easier not only for technicians but users to manage their assets,” Randall said.

Another core element of HGAP’s strategy is to go beyond supplying customers with air compressors and related solutions based on specifications alone. The goal is to dig deeper into issues customers want to address and the problems they want to solve, Andrew said.

“The key here is really understanding the customer and what they need. No customer needs an air compressor. They need what an air compressor provides,” he said. “When you start to have that discussion, it’s not about design. It’s about here’s what works best for the customer,” he said.

“Then the question gets back to, ‘How do we have the right regional customer requirements satisfied?’ ” said Randall. “To David’s point, sometimes it’s asking the extra question and maybe providing a solution or an opportunity customers weren’t even thinking about.”

More insight often leads to options, the team pointed out, citing Sullair’s Spiral Valve Technology as an example. Introduced in 1984 and refined since then, the technology is an alternative to Variable Speed Drives (VSD) as a capacity control method to efficiently manage changes in air compressor demand, in turn, reducing the amount of air compressed. The energy-saving solution is ideally suited for hot climates and dusty environments, as well as high altitude applications.

Reliability Remains Top Priority

Reliability, the HGAP team noted, is what most HGAP customers have said they want more than anything out of a compressed air system. As such, the company will continue to incorporate proven design features into products as a way to enhance air compressor reliability and longevity.

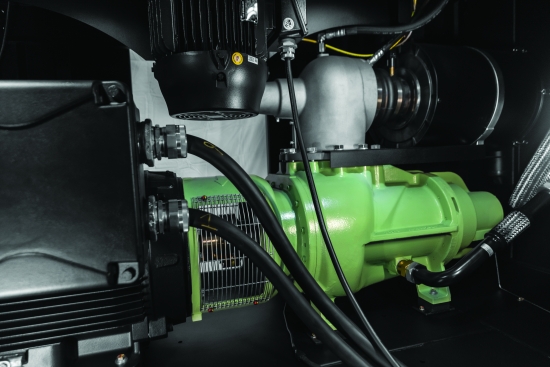

Randall cited the company’s recent initiative to enhance the reliability and performance of its 23 Series, 26 Series, and 32 Series airends.

“We went through and looked at where we were seeing problems,” he said. “We eliminated all of the external oil piping and tubing to make them internal galleries. We eliminated as many as 30 potential leak points to where you now only have two or three oil points going in and a single discharge going out. We also looked at bearing loading and bearing life and put lot of science into things and really amped up the efficiency side of it.”

Sullair 23 Series, 26 Series, and 32 Series airends have been re-engineered for even greater efficiency and reliability.

Randall said HGAP is incorporating the same enhancements into its Certified REMAN Airend Program.

“The cast for our airends is so durable that we can now use some of our learnings to make older airends more efficient as remanufactured airends,” he said, adding how remanufactured components on an air compressor equates to sustainability. “We’re now on the second and third life for some cast components. We’re eliminating the use of virgin material but still satisfying the customer need.”

Values of Hitachi Help Mold the Future

Randall said he appreciates the opportunity to lead a company with roots in the industry that dates to 1911 when Hitachi began manufacturing air compressors, which is in addition to Sullair’s rich history in rotary screw technology. He said HGAP fully embraces Hitachi’s values of pioneering spirit, harmony, and sincerity as it looks to mold its future.

“When we work with our colleagues in Japan, we think about having a pioneering spirit and how we can continue to bring new products and services to market that not only satisfy the customer need but also a societal need,” he said.

“The concept of harmony,” Randall said, “is about how we work together so we can get products and services to markets faster. Embracing harmony allows us to use the combined strength of 200-plus engineers as an example. Whether they’re in China, Japan, or the United States, we’re able to work together on solutions that satisfy the customers’ needs.”

Sincerity, Randall said, will be nothing less than essential to the overall success of HGAP and its partners.

“Let’s make sure we’re open and honest about our challenges. Let’s continue to make sure we’re putting together plans and resources so we can continue to deliver those things that our customers can count on,” he said.

For more information on Hitachi Global Air Power visit https://www.hitachiglobalairpower.com/.

Images courtesy of Hitachi Global Air Power.

To read similar Air Compressor Technology articles, visit https://www.airbestpractices.com/technology/air-compressors.

Visit our Webinar Archives to listen to expert presentations on Air Compressor Technology at

https://www.airbestpractices.com/webinars.