The 2023 Hannover Messe was held April 17-21 at the Fairgrounds in Hannover, Germany. As the first installment of the show since the COVID virus shut things down, it was great to see the European industry back together in one hall. I have been visiting this event, since 1992, and it’s great to see old friends, new companies and the latest company and technology developments of firms in the compressed air industry. This article will provide readers with a sampling of compressed air technologies seen. We regret not being able to include all exhibitors or visits made due to article length considerations.

The IFM recruiting bus at the 2023 Hannover Messe!

Air Compressor Technology

Kaeser had an impressive presence at the Hannover Messe with a 2-floor booth and an outside pavilion featuring their Kaeser Air System Enclosure products with fully containerized compressed air systems. Kaeser Compressors President, Frank Mueller, gave me a booth tour. The big thing that caught my eye was a focus on oil-free technology starting with the new CSG-2 50-125 horsepower, oil-free rotary screw air compressors with airends designed and built by Kaeser. R&D has clearly been busy, all cooling lines are internal in this two-stage unit. There was also a fully enclosed I.Comp8 Tower T oil-free piston machine. The displayed PillAerator oil-free turbo blower, using magnetic bearings, made me wonder how long it will be before we see this technology, from Kaeser, at 7 bar (100 psi)? Lastly, I was impressed to see the new KM Series line of instrumentation products measuring ambient air temperature/pressure, pressure, dew point and flow.

Frank Mueller, from Kaeser Compressors, next to their new CSG-2 oil-free air compressor featuring Kaeser airends.

On the event’s first day, I walked up to Vice President David Andrews and he promptly said, “Hey Rod, as of five minutes ago, I no longer work for Sullair.” He seemed quite serene so I knew he was up to something. I waited quizzically until he said, “We’ve just announced the creation of Hitachi Global Air Power – they are my new employer!” The very important strategic news is that Sullair is now a major brand to be developed by the newly formed Company, Hitachi Global Air Power. In my humble opinion, this is a brilliant strategic decision. Their booth featured Sullair branded machines in the trademark green. They included the DS Series oil-free (45 to 75 kW) rotary screw air compressor with features known to fans of the LS Series including lift-off doors for easy service and a new controller with enhancements to, but building from, the LS Series electronic controller.

David Andrews in front of a Sullair DS Series oil-free rotary screw air compressor at the Hitachi Global Air Power booth.

Hertz Kompressoren had an impressive booth within the booth of parent company DALGAKIRAN. They showed me their new IMPETUS Series of 22-315 kW 2-stage rotary screw air compressors. With VSD as an option, the 22—75 kW models use a permanent magnet motor while the 90-315 kW range uses asynchronous IE4 motors. A lot of attention to quality showed with oil cooling between the 1st and 2nd stage, a separate intake filter from outside the cabinet and a VSD driven fan on the oil-side cooler.

Gökhan Çivkarolu at the Hertz Kompressoren booth.

At the Tamturbo booth, Hannu Heinonen announced having won some exciting contracts in the U.S. Random factoid, did you know Hannu is an avid Arctic snowmobiler? The heat recovery packages are almost always used, he told me, in their 200 to 400 horsepower projects due to the tremendous energy efficiencies they provide. Unlike oil-free rotary screw air compressors, they reminded me that Tamturbo’s 100% oil-free turbo air compressors do not have any oil in the machine because the active magnetic bearings are “Touch-Free”.

Heli Malinen, Thorsten Frehe and Hannu Heinonen at the Tamturbo booth (left to right).

ALKIN is a manufacturer of high pressure compressed air and breathing air compressors and boosters with pressures up to 6000 psi. Industry veteran Nitin Shanbhag is the President of ALKIN Compressors and he walked me around the booth. Excited about the challenge, Nitin told me the firm is committed to growing U.S. market share in the high-pressure market and provides product warehousing and technical support in New Jersey.

Engin Tüjümet, Nitin Shanbhag and Emre Tüjümet at the ALKIN booth (left to right).

ELGi is proudly celebrating, in 2023, their 10-year anniversary in the United States. Senior Vice President Malcolm Lindsay said, “After ten years and together with our sales and service channel partners, we are very proud to celebrate, the installation of 10,000 rotary screw compressors, all under our unlimited air-end warranty.” I was impressed to hear ELGi was awarded the 2019 Deming Prize for Quality Management. ELGi founder Jairam Varadaj (also known as Dr. J!) said, “We are the first air compressor manufacturer to win the Deming Prize. This recognition, along with the 10-year performance of our products in the U.S., helps people truly believe in our total focus on quality and reliability – and understand why our warranty can be so strong.” I was particularly impressed by their water-injected AB22V single-stage rotary screw air compressor. This unit uses condensed water, which one doesn’t need to treat, to lubricate the air compressor and the VSD can turn down to 20% of load. Outlet air temperatures are low and most units are air-cooled with max ambient temperature ratings of 120 ºF (50 ºC).

Jaraim Varadaj and Malcolm Lindsay, at the ELGi booth (left to right), next to their AB22V single-stage, water-injected, rotary screw air compressor.

Industry veteran Bill Kennedy was at the Mattei Compressors booth and was excited to talk about their new RVX 75 ultra performance single-stage rotary vane air compressor. Bill said, “This new RVX 75 kW model has a market-leading specific energy performance. We are truly excited about what this product line can do in terms of energy efficiency.”

Bill Kennedy, at the Mattei Compressors booth, next to their new RVX Series rotary vane air compressor.

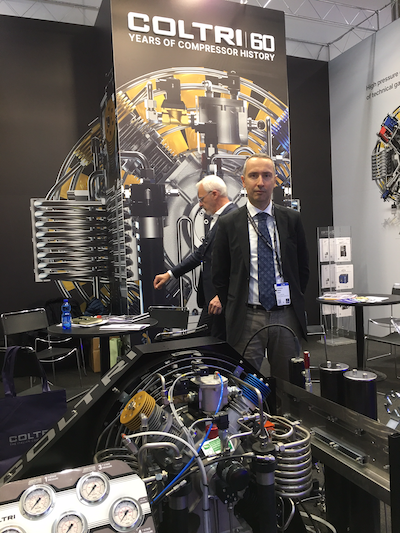

COLTRI is a manufacturer of high-pressure compressors and boosters for compressed air and nitrogen. They had a 40-bar nitrogen compressor for laser cutting and metal stamping in the booth and also their AC VII booster able to take 2-5 bar air or nitrogen and boost it to 420 bar. Celebrating the 60th anniversary of COLTRI, industry veteran Andrea Fabris (JOSIMO) is representing them for their entry into the U.S. market.

Andrea Bruni, at the COLTRI Compressors booth, showing their ACE VII Booster for nitrogen or compressed air.

JOSVAL has been manufacturing air compressors for a long time. Owners Manuel and sister Marga Loren presented a whole new product portfolio with the development of sound attenuated piston compressors, a full range of rotary screw air compressors and a complete extended warranty program. The IBERUS rotary screw air compressor line, for example, ranges from 7.5 to 60 horsepower and comes with a strong 15-year extended warranty plan.

Enrique Fernandez, Ignacio Tabuenca, Marga Loren and Manuel Loren at the Josval booth, next to their new IBERUS rotary screw air compressor.

IES Compressors invited me to see their new 3CT Carbon Capture Compressor technology. Developed in conjunction with a government research center, the 3CT rotary screw air compressor is equipped with an advanced system of filtering membranes through which passes a capture fluid able to absorb about 180 ppm of the CO2 present. The removed CO2 gas is stored in an appropriate container and is ready for use in another process or for sale. I don’t know how the CO2 market works, but the technology was quite ingenious leveraging the temperature differences of the fluid circuits in an air compressor.

Mariano Rigotto, at the IES Air Compressors booth, next to their 3CT Carbon Capture Compressor.

Compressed Air Purification & Piping

Mikropor continues their march towards larger global market shares, in compressed air purification and HVAC filtration. Their booth reflected it in size and in the number of visitors-and not just during the after-hours party featuring a good band! Compressed air industry veteran Volkan Ayhan said their “highly experienced group of U.S. Regional Managers” continues to drive growth with all their compressed air and gas purification, onsite gas generation and breathing air products. They displayed a new MTD Series Turbo Air Dryer designed for flow ranges of 5,850 to 17,500 cfm (10,000 to 30,000 Nm3/h) at 100 psig (7 bar). The thermal mass design provides energy savings at partial loads while product literature says it can maintain a stable 38 ºF (3 ºC) pressure dew point. The units feature scroll and screw refrigeration compressors.

The entire Mikropor team at their booth.

Nano is now part of Atlas Copco and is expanding globally with their range of compressed air purification and nitrogen/oxygen generation products. One of the “nano originals”, Mark Lauterwasser said their growth in nitrogen and oxygen generation products has been very strong and that they are excited about taking nano global. He showed me their new Gen2 Mini nitrogen generator designed for laboratories and wine production. Their packaging has always been cutting edge.

Mark Lauterwasser, at the nano booth, next to their new Gen2 Mini small flow nitrogen generator.

When I’ve walked into a Solberg booth over the years, I’ve known I can always expect a friendly face, to learn something new and to have a “Solberg refreshment on tap.” They set the bar pretty high and this year was no different. Tor Solberg showed me their new Foam Dissipation Element designed to protect dry pumps increasingly being used in breweries (instead of liquid rings) in order to save water. He said this new technology uses UB filter media. He also showed me some interesting vapor condensation filters used in plastics and plastic extrusion markets. The filters have coils with refrigerant provoking the vapor to condense so it can be filtered.

Tor Solberg, at the Solberg booth, next to their new Foam Dissipation Filter Element for dry pumps in breweries.

The Pentair booth was displaying their membrane technology for drying compressed air and other gases. What surprised me was when their Sales Director Carlos Rincon-Toro told me they were very active in using their membranes for humidifying applications in automation and EV battery manufacturing. They also surprised me when they said they’ve recently used membrane dryers to achieve a -75 ºC pressure dew point in an application.

We ran into Jon Schwartzman, from AIRpipe USA, and followed him over to his booth. We met Frederic Dugast, who is the General Manager for AIRpipe Europe. He explained their head office for the European operation is located in Nantes, France. Products are being supplied to the European market from a central stock in Belgium. He said they have established their business in many European countries and are now expanding to other European areas. AIRpipe is a manufacturer of in-house engineered aluminum & stainless steel piping systems for compressed air, vacuum and non-flammable gases like welding gases, N2 and CO2. For other industrial mediums they offer the AQUApipe stainless steel piping system.

Jeroen Le Large, Fred Dugast, Laurence Robic, Tobias Peters and Jörg Hädrich at the AIRpipe Europe booth.

Compressed Air Measurement Technology

Compressed air measurement appears to be growing significantly as a market. The products being sold the most are flow meters also able to measure at least pressure and then dew point meters. This market is clearly still in its’ early stages of development and the companies pioneering the way with measurement technologies are providing industry with a great service to help this on-site utility be managed more sustainably and safely.

Martin Zeller, from CS Instruments, spent time with me talking about their new UltraCam thermal imaging leak detector and their focus on precise measurement accuracy with flow meters. He explained their existing ultrasonic leak detectors, the LD 500 and LD 510 have been well accepted due to the automatic laser distance management feature which automatically adjust the leak flow estimate for distance. The new UltraCam thermal imaging attachment can be retrofitted on LD products built after August 2020. Martin said the list price for the LD 500, with the new UltraCam (including cloud software), is $8,000 – an eye-opening price point vs. models currently in the market. We also discussed flow metering at length and Martin said their philosophy is to provide the highest possible accuracy in flow measurements by taking time up front to determine the velocity of the air in the application with the customer. The velocity will cause them to customize the flow meter sensor to one of four velocities ranging from low to high. Low speed for example is 50 meters per second, standard is 93 m/s and high-speed is 224 m/s.

Martin Zeller, at the CS Instruments booth, demonstrating their newest leak detector, the new LD 500 with UltraCam thermal imaging.

VPInstruments had a Sustainability Superhero cut-out in their booth which made for many humorous photos. President Pascal Van Putten showed me their new VP Flow Scope M inline flow meter. I like how one can exchange the sensor cartridge, when it’s time for calibration. They said this sensor cartridge philosophy will be extending out to the entire line. There was also a new auditor tool, a suitcase called the VPVision Mobile – with metering devices, a data logger and the VPVision software to display the data all included.

Cynthia Kuipers, Menno Verbeek and Pascal Van Putten at the VPInstruments booth in front of their new VPVision Mobile auditor tool (left to right).

Thomas Fischer and Jan Hoetzel, at the SUTO ITEC booth, told me the growth of their Company continues to be very strong saying, “Flow, pressure and dew point measurement continues to drive the growth.” Their product portfolio is clearly growing as they showed me their new S605 Breathing Air Analyzer (fire fighter systems) and their S451 flow meter certified (ATEX, IECEX, GB) for outdoor and explosive environments. All their meters can now be configured with cell phones.

Thomas Fischer and Jan Hoetzel at the SUTO ITEC booth (left to right).

A surprise for me has been the size of IFM Efector, a manufacturer of sensors and measurement products for automation. Turns out they are a privately held German firm with approx. $1.3 billion in sales! Their booth reflected this with a semi-truck parked next to it which I guess they use for recruiting. I only knew them as a mysterious flow meter manufacturer, whose products I saw, in the hundreds, at a certain tire manufacturing plant, who then didn’t allow me to write a story about it - after I wrote it. Yes, I’m still grumpy about it because it was one of the most amazing “best practice” cases I’ve ever seen on the use of compressed air flow meters! Anyways, I met with Marcel-Andre Boi, at the IFM booth, and he reviewed the newer versions of their SD Series flow/pressure meters which I’d seen back in the day. One thing they do is to “digitize” their measurement data so it can be efficiently integrated into the IT infrastructure supporting automation. He invited me to visit their U.S. production center in Malvern, PA and said compressed air flow/pressure metering is becoming a higher priority product for them due to the market growth potential they see due to the sustainability impact of improved compressed air systems.

Marcel-Andre Boi, at the IFM booth, in front of their SD Series flow and pressure meters.

Emerson Discrete Automation is a $2.6 billion division of $13.8 billion parent company Emerson. Discrete Automation has major process measurement and pneumatic automation brands like Fischer Rosemount, Rexroth, ASCO and Numatics. I have been very impressed by their focus optimizing the demand side of compressed air systems through their expertise with on-machine pneumatics. They are providing clients with retrofittable time-of-flight (TOF) sensors monitoring pneumatic cylinder performance. This is part of leak audits and an overall compressed air demand-side auditing effort which has already netted some huge wins for some clients in compressed air related energy savings. Director Amit Patel said, “compressed air monitoring (pressure, temperature, flow) with our AF2 modules is one of the first steps we take with each client on this journey.”

Jay Gatz in front of the AF Series compressed air flow and pressure monitoring module at the Emerson Discrete Automation booth.

For similar articles on Compressed Air Technology please visit https://www.airbestpractices.com/technology.

Visit our Webinar Archives to listen to expert presentations on Compressed Air Technology at

https://www.airbestpractices.com/webinars.