Compact Kars, Inc. is a Certified Mercedes Benz Collision Repair Center based in Clarksburg, New Jersey.

|

Tom Elder, President of Compact Kars, Inc. |

||

Exceeding Expectations

Compact Kars, Inc. is a Certified Mercedes Benz Collision Repair Center based in Clarksburg, New Jersey. Launched in 1975, Compact Kars has grown to employ over twenty people in their 24,000 square-foot, 39-bay facility. ““The shop has been repairing Mercedes Benz automobiles since 1984, and we are very proud of our reputation and spare no expense to exceed customer needs,” says Tom Elder, the Founder and President of Compact Kars.

Mercedes Benz conducts a yearly audit to ensure their rigorous certification requirements are met. This includes owning Mercedes Benz factory-approved equipment, meeting training requirements for employees, and conducting environmentally-friendly business practices. “The Mercedes Benz creed is to exceed expectations,” stated Mr. Elder, “When a customer purchases a Mercedes Benz, there is a level of expectation that will not be compromised. This includes complying with the latest EPA VOC Paint Standards.”

The New U.S. EPA 6H VOC Paint Standard

The U.S. EPA (Environmental Protection Agency) has issued the National Emission Standard for Hazardous Air Pollutants, NESHAP (Subpart HHHHHH) Final Rule¹ . This “6H” Standard focuses on controlling air emissions from paint stripping and surface coating operations. The compliance deadline, for the new 6H standard, is January 10, 2011.

Collision repair centers, who spray-paint cars, have historically used paints and solvents with the following Volatile Organic Compounds (VOC) and Hazardous Air Pollutants (HAP)² .

• Diisocyanates - the leading cause of occupational asthma

• Organic Solvents such as toluene and ethylbenzene have been lined to numerous health effects

• Heavy metals, such as hexavalent chromium, which causes lung cancer; and lead which has been linked to nerve and brain damage

New Waterborne Paints Reduce VOC’s Significantly

The new paint specification, for Mercedes Benz Collison Repair Centers like Compact Kars, is for waterborne paints. “The new waterborne paints contain only two (2) pounds of volatile organic compounds (VOC) compared to 5.65 pounds per gallon of VOC’s present in solvent-based paints,” according to Mr. Elder. “For this reason, Mercedes Benz is asking all certified facilities to convert to waterborne paints.”

According to Mr. Elder, Mercedes Benz has tested all the replacement waterborne paints. “Often, the Glasurit 90 Line is the factory OEM-specified paint.” Information from Glasurit explains that the 90 Line makes conversion “easier”. For example, the aqueous mixing base and the pigmented base are easy to homogenize with its’ 2:1 mixing ratio. Glasurit says the 90 Line also uses standard HVLP (high-volume low-pressure) spraying techniques used in the industry. Other favorable factors include shorter flash-off intervals and shorter dwell time in the booth – compared to other waterborne paints³ .

|

|

The Glasurit 90 Line Waterborne Paint is Often Used for Mercedes Benz Vehicles

Mr. Elder is a past president and continues to be very active in the Alliance of Automotive Service Providers of New Jersey (AASP/NJ). He is also the Chairman of the board of Auto Body Distributing, New Jersey’s buying co-op for collision repairers .This alliance helps members make the transition to waterborne paints through a buying group and also provides best practice education. A recent initiative by the AASP/NJ has been to join the New Jersey Green Automotive Repair Program (NJGARP). The NJGARP, launched in April 2009, encourages automotive repair facilities in New Jersey to implement environmentally-friendly business practices and become certified as “green” businesses. Mr Elder said, “We have developed the guidelines for a green body shop. You qualify by accumulating 450 points and converting to waterborne low VOC can assist a shop in accumulating additional points towards this goal.”

Compact Kars converted to waterborne paints and during the transition experienced some extra costs. “We have invested in HVLP spray guns for the waterbased paints and now have two paint recycling systems – one for waterbased and another one for solvent-based paints,” said Mr. Elder. “We also have new paint mixing processes to learn and have had to upgrade the compressed air system.”

|

|

|||||||

|

Air & Gas Technologies, Inc. has provided, since 1995, product, parts, service and complete installations of compressed air and process gas compressor systems. Expertise and experience includes high pressure breathing air compressors used for both SCBA & SCUBA applications and the design/build/maintenance of Compressed Natural Gas (CNG) Refueling Station infrastructure. For more info visit www.airgastech.com |

|||||||

|

|||||||

Air & Gas Technologies has extensive experience designing, building, and maintaining Compressed Natural Gas (CNG) Refueling Station Infrastructure |

Waterborne Paints: Two Impacts on the Compressed Air System

Compressed air is a critical power source in a collision repair center. If the compressed air system is down or working inappropriately, work will grind to a halt. “I consider compressed air to be the life-blood of a collision center,” said Mr. Elder. “I always find it ironic that a \$18 million dollar collision repair center often has an antiquated 7.5 horsepower reciprocating air compressor located in a closet in the back of their parts department. Equally bad is the use of rudimentary air treatment products like the single-cannister desiccant dryers found at the point-of-use.” The conversion to waterborne paints forced Compact Kars to look at two factors in their compressed air system: increased air demand and higher air quality requirements.

|

|||

The new Hydrovane RS regulated-speed air compressor at Compact Kars. |

|||

Increased Compressed Air Demand

Paint booths, in collision repair centers, can consume a significant percentage of total shop compressed air demand. This percentage has increased as the base coat of waterborne paints takes longer to evaporate and more compressed air is needed to speed up the drying process. “We use vortex dryers to reduce the booth time of a piece painted with waterborne paints. We have one or two compressed air hoses wide open when drying,” said Mr. Elder. “Our air compressor couldn’t keep up, particularly on hot, humid days and we asked Brian Keelen, from Air & Gas Technologies, to come take a look at providing a solution.”

Air & Gas Technologies is a compressed air sales and service company based in Cliffwood Beach, New Jersey. “After analyzing air demand, we found that the paint booths were now consuming 60% of the compressed air and that shop pressure would fall when the vortex dryers were running,” said Mr. Keelen from Air & Gas. “We already had centralized and secondary compressed air storage in place to reduce the impact of the intermittent demand – the shop simply needed more air flow and the ability to turn-down when the vortex dryers were not running.”

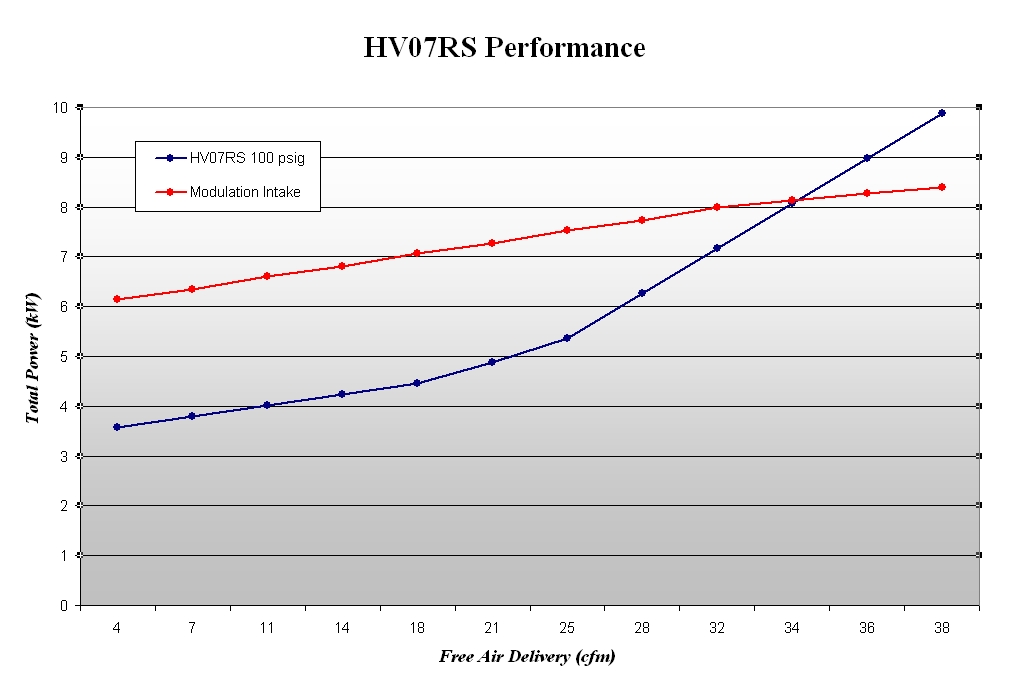

The regulated-speed Hydrovane HVOYRS model uses less energy, under partial load conditions, than do typical modulation-intake air compressors. |

The decision was made to install a ten horsepower Hydrovane rotary vane air compressor with RS regulated-speed controls. “The installation technician from Air & Gas was outstanding”, said Mr. Elder. “He told us how the Hydrovane’s on-board computer works and set up how to stage our air compressors.” The new Hydrovane acts as the base-load air compressor now and the older rotary screw compressor acts as the back-up.

The new 10 horsepower Hydrovane rotary vane air compressor runs at only 1750 revolutions-per-minute (RPM). This compares very favorably to male rotor speeds of rotary screw compressors ranging from 2,500 to 9,000 RPM. The lower rotating speeds of the rotary vane compressor design mean longer bearing and airend life.

The fact that the enclosed Hydrovane is very quiet is not lost on the employees at Compact Kars, Inc. “The rotary vane air compressor has a 66 dba rating and we have also installed ducting to evacuate the heat in the summer and to use it in the winter,” said Mr. Keelen. Mr. Elder continued, “We purchased the extended warranty and use the new synthetic oils that can last a full year. This way we know we will have worry-free operation with one major maintenance per year.”

Higher Air Quality Requirements

With a career in collision repair that started in the late 1960’s, Mr. Elder has seen quite an evolution with compressed air systems. “I remember we couldn’t hear each other whenever the old 5 horsepower tank-mounted, “iron lung” reciprocating air compressor turned on. So, I enclosed it with a plywood cabinet to reduce the noise – this just made it run hotter and worse.” Mr. Elder continued, “Finally, I placed it outside the building – with no air dryer of course. The result was fish-eye paint problems on cold days and on hot days - a machine that couldn’t keep up with air demand and that used a lot of oil.” “Quality compressed air is the life-blood of our facility - making possible our polishing and sanding, cleaning, assembly, disassembly, tire-mounting, and painting processes.”

Mercedes Benz Collision Repair Centers must have systems providing clean, dry compressed air containing no moisture, solid particulates, or oil. The use of waterborne paints has accentuated the importance of this specification. “With the intermittent demand profile here, we installed a cycling refrigerated air dryer,” said Mr. Keelen. “This allows for a steady 38 F pressure dewpoint and energy-savings as the refrigeration compressor cycles on and off with the intermittent compressed air demands from the paint booths.” Coalescing filters have also been installed to remove solid particulates and oil from the compressed air system.

Vortex Dryers Speed Up the Drying Process

Compact Kars Specializes in Mercedes Benz, Honda, and Volkswagen Automobiles.

Conclusion

The U.S. EPA (Environmental Protection Agency) has issued the National Emission Standard for Hazardous Air Pollutants, NESHAP (Subpart HHHHHH) Final Rule. This “6H” Standard focuses on controlling air emissions from paint stripping and surface coating operations. Moving to waterborne paints provides benefits to the work and global environment. Compact Kars, led by Mr. Tom Elder, is embracing this change and has made investments to make this possible. One investment has included upgrading the compressed air system to meet higher demand and air quality requirements.

For more information, please contact Mr. Brian Keelen, Air & Gas Technologies, 42 Industrial Drive, Cliffwood Beach, NJ 07735, tel: 732-566-7227, email: bkeelen@airgastech.com, www.airgastech.com

¹Source: National Emission Standards for Hazardous Air Pollutants NESHAP.

²Source: “Design for the Environment, Automotive Refinishing Partnership”.

³Source: www.glasurit.com.