Compressed air is a critical utility widely used throughout the food industry. Being aware of the composition of compressed air used in your plant is key to avoiding product contamination. Your task is to assess the activities and operations that can harm a product, the extent to which a product can be harmed, and how likely it is that product harm will occur. Assessing product contamination is a multi-step process in which you must identify the important risks, prioritize them for management, and take reasonable steps to remove or reduce the chance of harm to the product, and, in particular, serious harm to the consumer.

Source of Potential Product Harm

Normal ambient air contains millions of inert particles, 5-25 grams of water, 1-5 micrograms of oil, and tens to hundreds of bacteria per cubic meter. In addition, the system itself can be a source of possible contamination, including pipe scale and rust, polymer shredded particles, rubber gasket pieces, sealing tape, metal shavings from pipe cuts, and even particles from charcoal filters and desiccant canisters. Sometimes condensed water or liquid oil already present in the system forms into an aerosol or vapor, creating yet another source of contamination.

Risk Assessment

Generally, the steps of assessing the risks of product contamination are as follows:

- Identify potential hazards

- Assess the risk of harm

- Assess existing control measures for adequacy

- Assess if extra controls are needed

- Schedule regular reviews to see if the controls are working

Identifying Hazards

A number of the components of ambient air become contaminants once they enter the compressed air stream. For the sake of this discussion, we will omit airborne microbes, as they were thoroughly discussed by Lee Scott in the Jan/Feb 2016 Issue of Compressed Best Practices® Magazine: /standards/food-grade-air/compressed-air-gmps-gfsi-food-safety-compliance.

When a compressed air component has a deleterious effect on the product, it is considered a compressed air contaminant. ISO 8573.1:2010 contains purity classes for components/contaminants in compressed air as shown in Table 1.

|

|

Table 1. ISO 8573-1:2010 — Part 1: Contaminants and Purity Classes |

|||||||

|

|

Purity Classes for Particles Maximum Number of Particles per Cubic Meter (m3) As a function of Particle Size, d b |

Purity Classes for Humidity and Liquid Water |

Purity Classes for Oil (liquid, aerosol, and vapor) |

|||||

|

Classa |

Maximum Number Of Particles per m3 |

Class |

Pressure Dew Point °C |

Class |

Concentration of Total Oil mg/m3 |

|||

|

0.1 < d ≤ 0.5 µm |

0.5 < d ≤ 1.0 µm |

1.0 < d ≤ 5.0 µm |

> 5 µm |

|||||

|

0 |

As specified by the equipment user or supplier and more stringent than class 1 |

|||||||

|

1 |

≤20,000 |

≤400 |

≤10 |

None |

1 |

≤-70 |

1 |

≤ 0.01 |

|

2 |

<400,000 |

≤6,000 |

≤100 |

None |

2 |

≤-40 |

2 |

≤ 0.1 |

|

3 |

not specified |

≤90,000 |

≤1,000 |

None |

3 |

≤-20 |

3 |

≤ 1 |

|

4 |

n/s |

n/s |

≤10,000 |

None |

4 |

≤+3 |

4 |

≤ 5 |

|

5 |

n/s |

n/s |

≤100,000 |

None |

5 |

≤+7 |

5 |

> 5 |

|

— |

Particles by Mass Concentration, CP, mg/m3 |

6 |

≤+10 |

|

||||

|

6 |

0 < CP ≤ 5 |

Class |

Concentration of Liquid Waterb, CW g/m3 |

|||||

|

7 |

5 < CP ≤ 10 |

|||||||

|

X |

CP >10 |

|||||||

|

|

||||||||

|

7 |

CW ≤ 0.5 |

|||||||

|

a To qualify for a class designation |

8 |

0.5 ≤ CW ≤ 5 |

||||||

|

b At reference conditions: 20°C, 100 kPa; 0 rel. water vapor pressure |

9 |

5 < CW ≤ 10 |

||||||

|

c See ISO 8573-1:2010 A.3.2.2 |

X |

CW > 10 |

||||||

Further, the British Retail Consortium (BRC) and the British Compressed Air Society (BCAS) have worked together to author a code of practice for the food and beverage industry. This code incorporates selections from the ISO 8573-1:2010 purity classes to arrive at recommendations for compressed air that comes into direct contact with the product, as well as compressed air that comes into indirect contact with the product, as seen in Table 2.

|

Table 2. A Brief Summary of Food and Beverage Grade Compressed Air Best Practice Guideline 102 Produced by the BRC and BCAS, July 18, 2013 |

|||||||

|

Product Contact |

Particles, maximum number per cubic meter by particle size range |

Humidity (Water Vapor), PDP °C |

Total Oil, mg/m3 |

ISO 8573-1 :2010 Equivalent |

|||

|

0.1-≤0.5 µm |

0.5-≤1 µm |

1-≤5 µm |

>5 µm |

||||

|

Direct |

≤400,000 |

≤6,000 |

≤100 |

None |

≤-40 |

≤0.01 |

2:2:1 |

|

Indirect |

≤400,000 |

≤6,000 |

≤100 |

None |

≤+3 |

≤0.1 |

2:4:2 |

These two specifications encompass most identifiable hazards. According to the Guideline, compressed air quality shall be tested and verified at least twice per year or per the manufacturer’s recommendations. Additional testing is also warranted whenever maintenance work or any activity that may affect the air quality is performed on the compressed air system. The Guideline recognizes the importance of compressed air quality and states that compressed air should now be part of the Pre-Requisite Program (PRP) in addition to the Hazard Analysis & Critical Control Points (HACCP) plan. Whenever maintenance is performed a representative selection of the air outlets shall be tested to confirm that the compressed air meets the relevant Purity Classes.

Assessing Risk of Harm

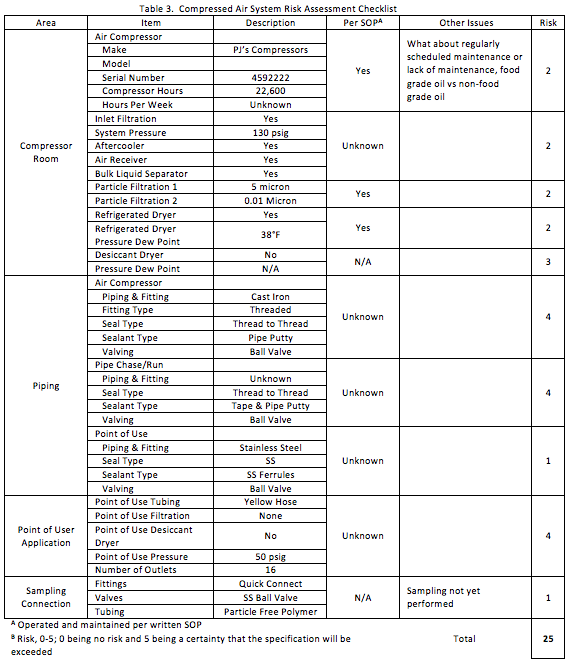

It may be helpful to catalog the elements of the compressed air system using something like the checklist in Table 3 below. The table allows you to assign the level of risk for each element with a numerical value (0 being no risk and 5 being certain risk).

In order to implement a monitoring plan, we must take stock of the compressed air system. Table 3 shows information that is not atypical of first-time air testing customers, although many of the entries made relating to piping, seals, sealants, and valves are not usually discovered prior to initial sampling. Based on this information, sampling can begin.

Table 4 lists materials for parts of a compressed air system, in order of what creates the best sampling environment. This table may be useful in assessing a system’s current risk of exceeding specifications.

|

Table 4. Material Preferences for Better Air Samples |

|

|

Based on Laser Particle Counter and Customer Experience |

|

|

Item |

Best > Better > Good > Not So Good > Poor |

|

Piping & Fittings |

Stainless Steel > Conductive Polymer > Nylon > Polyester > Vinyl > Polyethylene > Copper > Glass > PTFE > Aluminum > Black Iron |

|

Seal Type |

Welded > SS Compression > Rubber O-Ring Compression > Threaded |

|

Sealant Type |

Welded > SS Ferrule > Polymer O-ring > PTFE Tape > Putty |

|

Valving |

Particle Free SS > SS Shut-off > Ball Valve w/ Conductive Polymer Seal > Ball Valve w/ Rubber Seal > Valve with Rubber Seal |

(Mostly relating to particles, but has some applicability to water and oil.)

Assessing Existing Controls

Staying current on regulations and publications will ensure knowledge of relevant standards. As for the present state of existing controls, there are two ways to monitor the quality of compressed air, either by testing all critical points of application, or by testing a random representative portion. While it can cost more to test all points, it is the only completely accurate method, since contamination can occur at any specific point without effecting others nearby. It may happen that the one point that isn’t tested ends up being the one that is contaminated.

Sampling strategies should be robust to ensure that the air provided to all points of use is of consistent quality. There are several sampling options to consider when assessing your system and its controls:

- Determine the percentage of sampling points to be tested over a given time period, e.g., 100%, 50%, 25%, etc.

- Take three samples: one close to the compressor, one midway through the system, one as far away from the purification as possible

- Sampling immediately before and after filter changes to weigh worst case scenarios against best case scenarios. Data obtained after 3-4 filter changes can be used to establish a trend analysis.

Safe Quality Food Standard: 5 Compressed Air Criteria - Webinar RecordingDownload the slides and watch the recording of the FREE webcast to learn:

|

Reviewing Efficacy of Controls

After receiving air sample test results, control efficacy will be made apparent. If the contaminant quantity falls within an acceptable threshold, by industry, then controls are adequate. However, if contaminants meet or exceed set standards, the options are to either reassess if the limits were set inappropriately, or to add additional controls, such as point of use filters.

Assessing Whether Additional Controls Are Needed

If, in the previous step, control efficacy proved inadequate to achieving the desired air purity rating, additional controls are, obviously, called for. Information about options may be available by industry or across industries, but the principle is to either add controls where none are in place, like adding a refrigerant dryer where there is none, or to add controls to existing controls, like adding a desiccant dryer to a refrigerant dryer. If, in the previous step, even the bottommost standards aren’t met, then basic controls need to be implemented immediately.

Scheduling Regular Review

This pertains to periodic reviews, the timeframes of which are designated by industry standard setters (BCAS recommends semi-annual). Quarterly testing is a good place to start in industries and geographies where testing is not strictly enforced. This can provide a baseline where no historic data exists, or, in cases where records already exist, can provide an accurate current assessment. Compressed air systems are not static, but dynamic—always changing. Component parts breakdown and malfunction, requiring maintenance or replacement, and there is not always an obvious indication that a device which is plugged in and running is not performing to standard. Regular testing hedges against the possibility of underperformance or non-performance.

Compressed air quality is a critical aspect of sanitation in the food industry. While regulation is still in its infant stages in some places, the core desire to protect consumers is enough to warrant regular air testing, as well as to ensure that equipment and processing environments are operating efficiently. Testing, while it does cost, stands to safeguard against the possibility of greater cost of damage or incident.

For more information please contact Trace Analytics at tel: 800-247-1024 x 4, email: TraceAnalytics@AirCheckLab.com or visit www.AirCheckLab.com.

To read similar Food Industry articles visit www.airbestpractices.com/industries/food or to learn about similar Food-Grade Air Standards visit www.airbestpractices.com/standards/food-grade-air.