Current Good Manufacturing Practices (cGMPs) under FSMA CFR Title 21 117.40 is the cornerstone of this food safety effort. Title 21 details the cleanability and cross contamination standards that plants must meet so that food is deemed safe. The following are tips for updating existing pneumatic systems in food and packaging and what to look for when purchasing new systems.

Ensure Compressed Air Does Not Contaminate Food

Ambient air contains a host of impurities, and in food plants adulterating and allergenic particles are added to the mix. Compressed air systems used in direct food contact and in motion control increase the density of these contaminants. It is vital that compressed air intended for direct contact with food and used at the end of the packaging line is made as clean as possible through filtration. For this reason, air filtration efficiency is the first line of defense for maintaining food safety.

However, cGMPs under CFR Title 21 117.40 do not define a required compressed air quality for direct contact with food and primary packing, which means the required filtration level must be determined by the end user. While many end users have determined their own air quality requirements, others may be unsure of recommended purity.

Organizations such as British Compressed Air Society (BCAS), 3A Sanitary Standards, VDMA Mechanical Engineering Industry, and Safe Quality Food (SQF) have published recommendations for specific air quality requirements. SQF recommends, for example, a final filtration stage of 0.01 micron with a filtration efficiency of 99.999% to be located at the point of use for direct food contact. If a plant has not created its own risk assessment, operations personnel may consider meeting the SQF standard. The compressed air preparation unit, shown below, has a filtration cascade meeting SQF. Assuming 7:4:4 (Solid particles: Water: Oil) air quality from the compressor, the resulting air quality of 1:4:2 also meets the ISO 8573-1:2010 standard that specifies purity classes of compressed air with respect to particles, water, and oil.

Festo MS Series air filter offers compressed air quality with 99.9999% efficiency.

Evaluate Additional Potential Contamination Points with Compressed Air

While compressed air intended for food contact is often addressed with proper filtration, there are several additional ways that compressed air can come into contact with food. For example, leaking fittings and tubing allow compressed air to exhaust in unexpected areas, which can often include areas directly over the food production. This means not only checking air nozzles and cylinders, but also finding and stopping leaks.

Preventive maintenance in terms of ongoing leak detection makes both food safety and operational sense; leak detection lowers the risk of indirect contamination and reduces energy costs. New technology can provide an automated means for detecting leaks. Once a baseline of air usage is established, these new intelligent devices alert plant personnel when too much air is consumed. The system automatically lowers pressure when a machine is idle to further save energy. By monitoring compressed air usage, leaks can often be discovered soon after they occur, and potential contamination issues prevented.

Another unintentional contamination source is the exhaust from valves controlling pneumatic components. Valves are often mounted near or above the food zone, and the air exhausting from the valve therefore poses a contamination hazard. Distance exhaust as much as possible from food and packaging and eliminate leaks that may blow contaminants into the atmosphere. If the valve cannot be moved, then the exhaust should be ducted to a safe area.

A quick exhaust located on a pneumatic actuator will also vent compressed air. As quick exhausts are usually mounted to the actuator that controls part of the process, this means quick exhausts generally expel air near the food zone. Quick exhausts should be avoided if possible by installing the controlling valve closer to the application. By utilizing IP69K rated valve manifolds, tubing lengths can be significantly reduced, which improves machine speed and often eliminates the need for a quick exhaust. If quick exhausts are still required, the exhaust should be ducted to a safe area.

Use Tubing That is FDA-Approved and Resistant to Cleaning Processes

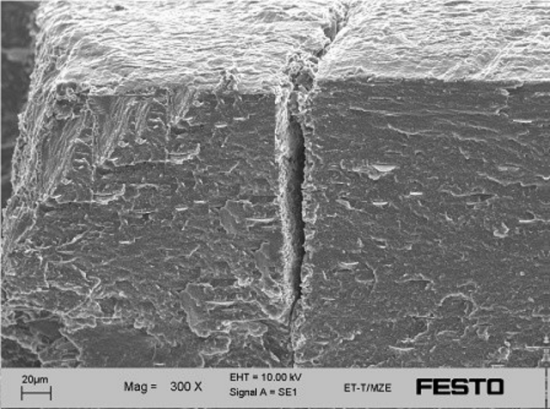

Plastics and elastomers that come into direct contact with food must comply with the directives of the FDA. The material must not give off or absorb any hazardous substances. Plastics and elastomers must also resist stress and be cleanable. Pneumatic tubing is at risk from various environmental influences as shown by the microscopic crack in the micrograph below – a crack that can house contaminants.

Scanning Electron Microscope micrograph shows cracking in incorrectly applied polymer tubing.

Approximately 90% of the defects on pneumatic tubing are traced to chemical, microbiological, or physical influences. Proper tubing selection and upgrade can minimize or eliminate failures due to these influences. Hydrolysis-resistant polyurethane (PUN-H) and Polytetrafluoroethylene ( PTFEN) tubing are ideally suited for use in the food industry. Both resist cleaning agents, microbes, and hydrolysis and are FDA compliant. PUN-H is more flexible and economical, while PTFEN is ideal for the harshest environments.

Begin Standardizing on Metric Actuators with G-Thread Fittings

Exposed pneumatic fitting threads provide the perfect breeding ground for contaminants as the small spaces between the threads are difficult to clean. Any fitting threads that cannot be avoided should therefore be closed off with suitable blanking caps and sealed.

There are several thread types used in pneumatic connections. BSPP, also known as G-thread used in metric-based pneumatic systems, left in the image below, is a parallel thread that features a clean design that eliminates exposed threads by sealing flush to a gasket. Utilizing G-threads wherever possible is an easy choice for improved FSMA compliance.

Tapered threads such as R-thread and NPT, center and right, seal by wedging threads together and through the use of sealing tape. These tapered threads risk contamination, not only through exposed threads, but also from metal fragments or flaking tape. For this reason, tapered fitting threads should be avoided for equipment in the food industry.

Parallel threads such as G-threads, left, secure to a sealing gasket and eliminate exposed threads. R-threads, center, and NPT, right, pose a contamination risk.

Make Sure Actuators Use Food Safe Lubricant

The U.S. has the strictest regulations on the use of lubricants and additives used in the food industry. Lubricating greases and oils must comply with CFR 21 178.3570. For equipment and components that will unavoidably come into occasional contact with foods and primary packaging, approved lubricants such as NSF-H1 must be used.

One potential food contaminate often overlooked is the lubricant in pneumatic cylinders. Close examination sometimes shows that grease is actually leaking from the nose of cylinders onto the food or primary packaging. It is imperative to audit cylinders for the NSH-H1 grease and replace those that do not have it.

In the washdown area, intensive cleaning can wash lubricating grease out of the cylinder. Not only does this pose a contamination problem, but also serves to impair cylinder operation. In the washdown area, utilize cylinders that feature FDA-approved dry-running seals. This will ensure clean, optimum operation even when the grease has been washed from the cylinder. Eliminating the use of components that fail because lubrication can be washed away is an example of how cleanability and cGMPs can improve uptime.

Replace Problem Components with Those Designed for Sanitary Applications

Many potential sources of contamination in food production such as bacteria, chemical influences, and corrosion particles can be eliminated by utilizing a few basic design considerations. To ensure that cleaning is safe, the materials used must not react with the cleaning agents or disinfectants. Machine parts must be resistant to corrosion and be mechanically and chemically stable.

This image shows the incorrect choice of materials for a pneumatic cylinder based on the amount of corrosion.

Contrast the components above with the actuator made of stainless steel shown below. Its design rigorously conforms to cGMP criteria. For example, there are no threads on the bearing cap and thus a reduced possibility of trapping contaminants. Its self-adjusting end position cushioning system is designed without contaminant susceptible adjusting screws. The actuator also utilizes NSF-H1 grease and FDA approved seals.

Stainless steel clean design pneumatic actuator.

Conduct Audits

Pneumatic systems are not static. Components wear out and vibrations can loosen fittings. New components are not only easier to clean, but also more rugged, performing better in harsh environments. It is not cost effective to replace every older machine, but it is worthwhile in terms of clean operation and overall equipment effectiveness (OEE) to maintain and upgrade pneumatics and automation components based on the findings of regularly scheduled audits.

Food safety tips for pneumatic systems

- Ensure compressed air intended for food contact does not contaminate food.

- Evaluate additional potential contamination points with compressed air.

- Ensure that pneumatic tubing is approved by the Food and Drug Administration (FDA) and is resistant to cleaning processes.

- Eliminate fittings that are difficult to clean.

- Ensure that actuators utilize food-safe grease.

- Eliminate components that easily corrode and are not designed for the food environment.

- Conduct audits at scheduled intervals.

All photos courtesy of Festo

About the Author

|

Steve Bain is the Industry Segment Manager for Food and Beverage for Festo US. A Chemical Engineer by degree, Steve worked for Kimberly-Clark and Ecolab in engineering roles before joining Festo in 2011. Steve works on a national level as a primary interface between Festo employees and customers to discuss food applications and compliance with food regulations. |

About Festo US

Festo is a leading manufacturer of pneumatic and electromechanical systems, components, and controls for process and industrial automation. For more information, visit www.festo.com.

To read similar Food & Beverage Industry articles, please visit https://www.airbestpractices.com/industries/food.

Visit our Webinar Archives to listen to expert presentations on Compressed Air Purification, Pneumatics and Piping at https://www.airbestpractices.com/webinars.