.jpg) |

|

Doosan Bobcat manufactures a wide array of industrial products and compact equipment at its 150-acre manufacturing campus in Statesville, North Carolina.

Doosan Bobcat, Inc., is well on its way to ensuring the name “Bobcat” earns its place as a well-known and trusted brand of air compressors in North America. That’s because the company has set the stage for strong growth given a strategic approach that combines world-class manufacturing capabilities and best business practices with a well-rounded product portfolio built on a legacy of reliability.

Branding and Manufacturing for Success

Doosan Bobcat, which has its North American headquarters in West Fargo, North Dakota, is comprised of a number of companies, two of which design and manufacture air compressors. One is Doosan Portable Power (DPP); the other is Doosan Industrial Air (DIA), which is responsible for the company’s suite of industrial compressed air products. Doosan Bobcat itself is part of the Doosan Group multinational corporation based in Seoul, South Korea.

Earlier this year, Doosan Bobcat announced it will manufacture and market industrial and portable air compressors under the Bobcat trade name in North America and other markets worldwide in 2024. With this change the portable power and industrial air product suites will undergo design and aesthetic changes in alignment with current Bobcat branding. While the branding strategy is new, the history of products that will soon go by the name “Bobcat” is far from it.

In 2007, DPP acquired Ingersoll Rand’s high quality portable air compressor models and business, which were first manufactured nearly 100 years ago. This made DPP a leader in market share of portable air compressors in the United States.

To continue meeting demand for air compressors, Doosan Bobcat invested heavily in U.S. manufacturing facilities including its one-million-square-foot manufacturing operation in Statesville, North Carolina. The $70 million expansion of the facility amplified its operations, where it now employs 930 people in office and factory positions and manufactures its line of portable air compressors from 185 cfm to 1,600 cfm, in addition to other Bobcat products like compact tractors, generators, light towers and mini track loaders. It also assembles and stocks the expanding line of Doosan Bobcat industrial air compressors.

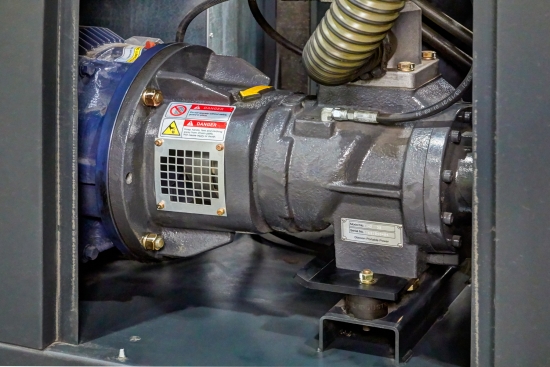

Doosan Bobcat rotary screw air compressors, with the recently announced Bobcat trade dress, in the finished product testing area at the Statesville, NC manufacturing campus.

Among its many attributes, the state-of-the-art Statesville plant boasts robust air compressor airend design and manufacturing capabilities. Airends, which start as a bar stock at the plant and end up as finished products, are thoroughly tested with an array of technologies including advanced Zeiss Coordinate Measurement Machines (CMMs). A team of lab technicians, in the operation’s fully climate-controlled dynamometer room, also test finished air compressors for performance.

“The lab has long been set up to test according to ISO 1217 and can test up to 1100 horsepower,” said Doosan Bobcat Senior Director of Global Engineering, Jamie Wilson. “We redesigned the entire portable line in 2008 and that experience has been valuable in designing the industrial air compressor product line. Outlet air flow tests, for example, use the specified test procedure using Circular Arc Venturi’s.”

Some of the other facility highlights of the operation include a full metal fabrication shop with laser cutting and metal punching machines, a newly installed Trumpf panel bending machine to reduce setup times from 30 minutes to 30 seconds, a welding shop with robotic welders, a four- to five-stage powder coating and baking line, a full electrical panel shop to support a wide variety of machines, and a pick-to-light parts warehousing system to ensure efficiency and accuracy in production and aftermarket support.

Jamie Wilson, Patrick Jakeway, Roderick Smith (Compressed Air Best Practices® Magazine) and Lance Mathern in the rotor machining production area (left to right).

Building on the Bobcat Brand

The story of Doosan Bobcat is incomplete without mention of the company’s history in the construction equipment industry, which dates to 1958 and its invention of the world’s first compact loader. The compact machine evolved into the original skid-steer loader, later branded as a “Bobcat” skid-steer loader. Mimicked by construction manufacturers worldwide, skid-steer loaders are widely recognized as one of the most popular machines on construction job sites today.

The Bobcat skid-steer loader has been traditionally recognized as one of the industry’s most dependable and well supported skid-steer loaders in the industry. It’s a tradition that continues with the Bobcat brand of air compressors, said Patrick Jakeway, Doosan Bobcat General Manager of Industrial Air.

“There’s an instant recognition of what it means,” Jakeway said of the Bobcat brand in North America. “We build durable products, we offer great support of our products, and we have great dealer relationships that date to over 80 years with certain product lines. All of our products follow that same philosophy.”

The company’s investment in the design, manufacturing and testing of airends is an example of Doosan Bobcat’s commitment to reliability. In addition to redesigning its airends in 2008 to enhance their reliability, the company formed a team of engineers committed to the ongoing development of airends that deliver ongoing durability and performance.

“You can’t go into this market and not exceed expectations from the customers’ perspective,” Jakeway said. “We have to provide that peace of mind and customer service focus. That capability is crucial.”

Lance Mathern, Doosan Bobcat Vice President of Industrial Products, Patrick Jakeway, Doosan Bobcat General Manager of Industrial Air and Jamie Wilson, Doosan Bobcat Senior Director of Global Engineering (left to right).

Doosan Bobcat manufactured airends use three stacked bearings and operate at a maximum of 1800 RPM’s (50 hp and above).

Powder coated air compressor airend housings ready for the assembly line.

Industrial Air Compressors in Expansion Mode

Meeting customer needs also requires a full selection of quality air compressors, said Jakeway, which is why Doosan Bobcat is beefing up its line of industrial machines to complement its extensive portable air compressor offering.

The Doosan Bobcat oil-flooded, rotary screw air compressors consist of fixed-speed and variable speed machines in the D30, D30vsd, D50, D50vsd, D75, D75vsd, D125, D125vsd, D150, D1250vsd,D200and D200vsd models. The number found in the nomenclature of Doosan Bobcat’s industrial air machines matches each unit’s horsepower rating. Later this year, the company will add skid-mounted, D10, D15 and D20 fixed-speed rotary screw machines to the lineup. Tank-mounted units are also in the planning stage. Later this year and into early next year, plans also call for the introduction of D250, D250vsd, D300, D300vsd, D400 and D400vsd fixed- and variable-speed models.

All Doosan Bobcat industrial air compressors are designed for ruggedness in keeping with the theme established long ago with the Bobcat compact equipment lineup and the company’s line of portable air compressors, said Jakeway. As an example, he said all fixed-speed air compressors ≥ 50 HP are rated to operate at a maximum of 1,800 RPMs.

“There’s less wear and tear on the units,” he said of the relatively low RPM rating. He also noted the use of premium, ie3 TEFC electric motors rated for long life, as well as a commitment to using more bearings in airends. “Ours use three stacked bearings,” he said. “A lot of companies only use two.”

Ease of use also takes precedence with Doosan Bobcat industrial air compressors, Jakeway said, pointing to the company’s highly intuitive Intelligent Control System (ICS) Controller found on fixed-speed and VSD air compressors. The controller features a seven-inch, color graphic display to readily monitor and adjust all key machine operating parameters, which can be viewed in English or Spanish. The unique test mode feature allows an operator to actuate, among other functions, the load solenoid, main motor contactor, wye motor contact and delta motor contactor straight from the controller without having to open the control panel. The auto-power-loss restart feature of the controller turns a machine back on in the event of a power outage.

Serviceability of air compressors is equally important, said Jakeway. Just some examples cited include a spacious design for ease of access to machine components, easily accessible air filters and coolers, and easy-to-remove service panels.

The highly intuitive Intelligent Control System features a 7-inch color graphic display to monitor and adjust all key machine operating parameters in English or Spanish.

High Levels of Service and Support

Designing and manufacturing reliable and easily serviced air compressors is one thing, but supporting the machines takes yet another level of commitment, said Lance Mathern, Doosan Bobcat Vice President of Industrial Products. Again, the company is taking its cue from the Bobcat tradition.

“We’re treating our air compressors just like we would with any Bobcat product,” said. “We offer great product support, and we have strong dealer relationships.”

Jakeway said support is delivered in the form of a robust team of engineers and technicians dedicated to helping customers with any and all issues associated with air compressors.

“Customer responsiveness is built in our DNA,” he said. “Folks running our service teams are 30- to 40-year veterans in the compressed air industry. They’re laser focused on customer satisfaction.”

Mathern said DIA goes beyond taking pride in its product support team as seen through a number of measures, such as tracking metrics to gauge the company’s responsiveness to customers’ needs.

“Our parts team answers 90 percent of calls in a minute or less, and we strive for an abandoned service call rate of less than five percent,” Mathern said. “If you call our 800-number, you’d press the button for the right department, and you’ll talk with a person.”

The people taking the calls, said Jakeway, are part of a dedicated air service and support team experienced in air compressor technologies and applications.

“It’s filled with industrial compressed air techs,” Jakeway said of the team. “They have their own cell numbers you can call. After hours, distributors can also get connected directly to our district field service reps.”

Product support for DIA also includes a five-year, bumper-to-bumper warranty on industrial air compressors and a commitment to offering extensive training services.

“Doosan Bobcat has long placed a big value on training,” Jakeway said. “Folks on our training staff used to work for some of the biggest industrial air compressor manufacturers, and they put together a really good training program.”

Spacious design provides service technicians with easy access to all key components of the rotary screw air compressor.

Sticking to the Game Plan

Mathern and Jakeway said excitement for the Bobcat line of industrial air compressors is beginning to build, especially since the name means something special to many equipment decision-makers in North America.

“It’s durable, it’s innovative and it’s versatile,” said Mathern regarding the Bobcat brand. “It just resonates with customers and what it means in terms of capability.”

The strategy moving forward, said Jakeway and Mathern is to continue to put the company’s plan into action.

“We’re going to keep growing. We’re going to keep doing the right thing by building a good durable product and providing great support,” Mathern said. “We know if we do that, then the rest will come.”

Images courtesy of Doosan Bobcat.

For more information on Doosan Bobcat’s industrial air compressors, visit https://doosanportablepower.com/na/en/equipment/industrial-air or email industrialairsales@doosan.com.

To read similar Air Compressor Technology articles, visit https://airbestpractices.com/technology/air-compressors.

Visit our Webinar Archives to listen to expert presentations on Air Compressor Technology at

https://www.airbestpractices.com/webinars.