Compressed air production in industrial facilities consumes 10% of electrical power, on average. While this can vary up or down, it is an industrial average, and is very significant in most plants.

Do you know how much of your power cost goes to producing compressed air? We’ll come back to this at the end of this article.

Up to 95% of the air compressor power turns into heat energy. Traditional air compressor technologies waste most of this energy.

Compressing air heats up the compressed air significantly – in traditional “oil-free” screw compressors, the temperature of the air can reach close to 400°F or even higher and then it has to be cooled. Compressed air is cooled either by air or by liquid. Most smaller compressors (<150hp) are air cooled. Then warm cooling air is ducted typically outside the facility without reusing the energy.

A high-speed turbo air compressor (left) next to a heat management unit.

Why not use the Hundreds of Kilowatts of Free Energy Available?

Cooling air flows for larger compressors are very high because of the low heat coefficient of (cooling) air. This is one of the main reasons why big air compressors >150hp and especially >300hp are more commonly liquid cooled. In theory, hundreds of kilowatts of “free” energy is available as heat/thermal energy to industrial facilities.

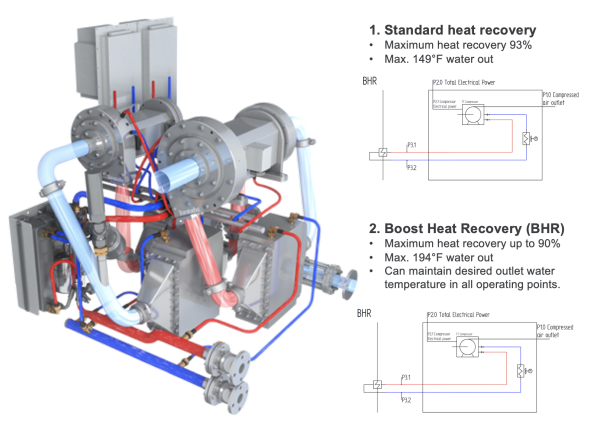

Tamturbo has put significant effort into designing the most efficient cooling method for our air compressors. In addition to capturing the heat of compression, we utilize liquid cooling to protect and recover the heat from the energy-intensive parts of our compressor – the frequency converters, electric motors and the turbo heads. This is built-in as a standard feature which captures up to 93% of the compressor input energy. Please note that this is a real recovery without using somewhat manipulated numbers from using the compressor as a heat pump as it is seen in some marketing materials, promising recovery over 100% of the input energy.

Boosted Heat Recovery BHR offers higher temperatures for heat energy recovery

In addition to recovery of significantly higher percentage of input energy, a patented Boosted Heat Recovery (BHR) offers liquid temperatures up to 194°F for heat energy recovery.

Click to enlarge.

Easy Integration to Plant System with Heat Management Unit HMU

The ability to integrate the heat recovery to plant systems is sometimes a source of hesitation for utilizing the heat energy from the compressor. A Heat Management Unit (HMU) makes the integration easy and affordable. Connections between the air compressor and the plant are in one compact module which minimizes the installation work and cost.

The Tamturbo HMU is an easy plug-and-play solution.

Save Significant Amounts of Energy and Money by Using the Heat

Long story short: Lower your total energy consumption by using the heat from the compressor heat recovery. Potential savings add up to 9% of total power cost of your facility. Common uses for the heat recovery energy are: heating the facilities during cold season, preheating boiler make up water, wash down of plant equipment or process lines, pasteurization, process water heating, and others.

Economics are attractive - multiply your existing compressed air power cost by 0.1 and then divide this number by the ratio of your cost of primary energy and electricity. For example (a case from Germany):

Compressed air power cost (electricity) $450,000/year

0,1*$450,000= $45,000/year (the unrecoverable compressed air energy cost), remainder $407,000 (90%) worth is recovered in the heat

$0,06/kWh / $0.14/kWh = 0,43 (ratio of heating energy cost (e.g. natural gas) and electrical energy cost

$407,000 x 0,43 = $175,000 (recovered heat as primary heat energy)

Saving: $175,000 when using Tamturbo compressors to heat up your processes.

Lower your carbon footprint and capture the energy savings with Tamturbo heat recovery.

About the Authors

Hannu Heinonen, is Vice President, Americas, Tamturbo, tel: 314-662-0188, email: hannu.heinonen@tamturbo.com; and Olli Kuismanen, Business Development, Tamturbo, tel: 358-40-766-5678, email: olli.kuismanen@tamturbo.com.

About Tamturbo

Tamturbo manufactures and sells industrial air compressors with 100% oil-free technology which is based on VSD controlled, high-speed turbo air compressors with active magnetic bearings making the air compressor wear free with industry’s lowest total cost of ownership. Without a single drop of oil in the system, air compressors are completely risk-free from oil adding any contamination in compressed air. For more information, visit www.tamturbo.com.

All photos courtesy of Tamturbo.

To read more Air Compressor Technology articles, please visit www.airbestpractices.com/technology/air-compressors.

Visit our Webinar Archives to listen to expert presentations on Air Compressor Technology at https://www.airbestpractices.com/webinars