FABTECH 2023, a leading event for metal forming, fabricating, welding, and finishing, successfully wrapped up its four-day run at Chicago's McCormick Place, achieving significant milestones for attendance, exhibitors, and show floor size. From September 11 – 14, FABTECH 2023 welcomed 40,505 attendees from across the globe—a 26% year-over-year gain in attendance compared to the 2022 event in Atlanta and a 40% increase compared to the 2021 event in Chicago. The 2023 show floor, spanning an impressive 825,325 square feet across three exhibit halls, featured an extensive showcase of over 1,500 world-class suppliers.

Fabtech 2023 drew 40,505 attendees focused on metal forming, fabricating, welding and finishing.

"We extend our sincere gratitude to the attendees, exhibitors, speakers, members, and everyone who joined us for FABTECH 2023 in Chicago," expressed Tracy Garcia, CEM, FABTECH Group Director at SME. "This year's event was an exceptional gathering, offering the industry a one-stop-shop for solutions with an expansive show floor that truly showcased the future of manufacturing.

FABTECH is North America’s largest metal forming, fabricating, welding, and finishing event. The event provides a convenient venue where you can meet with world-class suppliers, see the latest industry products and developments, and find the solutions to improve productivity and increase profits. FABTECH is made possible by its five event partners, all of whom represent the varied and diverse makeup of the manufacturing industry. They include the American Welding Society, the Chemical Coaters Association International, the Fabricators & Manufacturers Association International, the Precision Metalforming Association and SME.

The objective of this article is to provide readers with a sampling of compressed air, nitrogen generation and chiller system technologies on display at the show. We regret not being able to include all exhibitors or visits made due to article length considerations.

Compressed Air System and Nitrogen Generation Technology

The Atlas Copco booth featured their compressed air system products, nitrogen generators, oxygen generators and AirNet aluminum piping for both compressed air and nitrogen. Cody Triscik was manning the booth and said, “We are unique in that we manufacture every component of a nitrogen generation system starting with the air compressors, dryers, filters and including PSA or membrane type nitrogen generators.” He said clients with carbon reduction goals really like the idea of eliminating deliveries from their gas suppliers and that the design of the NGP+ nitrogen generator has a leading air to gas efficiency ratio.

Cody Triscik next to a G Series rotary screw air compressor and a NGP10+ nitrogen generator at the Atlas Copco booth.

Kaeser Compressors’ booth featured their Kaeser Air System Enclosure (KASE) with standard products from 40 to 300 horsepower. Michael Camber said that depending upon the size of the metal fabricator, they might purchase anywhere from a 2 x 20 hp system to a 3 x 100 hp system. He said this market also purchases their skid systems for laser cutting using compressed air. These are low to high-pressure systems including boosters to 350 to 500 psig. Lastly, I was impressed to see, integrated into the KASE, the new KM Series line of instrumentation products measuring ambient air temperature/pressure, pressure, dew point and flow.

Michael Camber, Mike Lanoie, Eva Johnson and Travis Taylor in front of a Kaeser Air System Enclosure (KASE) at the Kaeser Compressors booth (left to right).

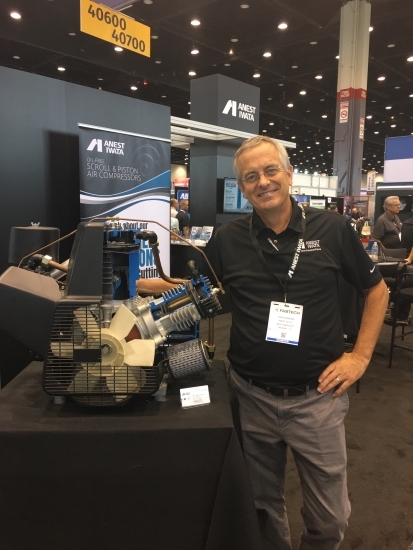

Anest Iwata is a major player in the metal coating industry with their comprehensive line-up of industrial spray equipment. This includes spray guns, pressure pots and double diaphragm pumps. The Anest Iwata oil-less scroll and piston air compressors were on display. Tom Fermann told me their oil-less piston has a MWP of 200 psi and pump sizes up to 15 hp. Their Cincinnati area facility is UL 508 approved and assembles tank-mounted oil-less piston packages to 30 hp. He said their oil-less scroll pump has a MWP of 145 psig with 2 to 10 hp pump models which they can turn into 2 to 60 hp packages.

Tom Fermann next to an oil-less piston compressor at the Anest Iwata booth.

BEKO Technologies had a surprise for me at their booth when they showed me their FDR Filter Dryer Regulator. Made for point of use machine protection it features a membrane dryer manufactured by BEKO in Atlanta. Apparently, this FDR was receiving a lot of attention from visitors to the booth. They were also displaying the Drypoint X desiccant dryer also manufactured in Atlanta.

Adrian Fernandez, Jason Brister, Randy Kinsey and Brian Speed in front of the DRYPOINT X heatless desiccant dryer at the BEKO Technologies booth (left to right).

Mikropor was displaying their new MTD Series Turbo Air Dryer designed for flow ranges of 5,850 to 17,500 cfm (10,000 to 30,000 Nm3/h) at 100 psig (7 bar). The thermal mass design provides energy savings at partial loads and feature TEFC motors. Vice President of Sales Chris Wells said that depending upon the size, the units feature R-410a scroll and R-407c screw refrigeration compressors. The experienced team of regional managers also raved about the growth in sales of their PSA (pressure swing adsorption) nitrogen generation product line.

Jeff Crutchfield, Mike Kinnucane, Chris Wells and Allan Hoerner in front of their MNG Series nitrogen generator at the Mikropor booth (left to right).

One of the busier booths at Fabtech was the Fluid-Aire Dynamics booth. National Sales Director Jeremy Gaitsch said, “Our sales team did a tremendous job of bringing customers to our booth.” The booth was busy presenting the PneuTech air compressor and dryer product lines and their UniPipe aluminum piping system. The higher (than normal) maximum working pressure ratings of the UniPipe system was generating many inquires for the 580 psi nitrogen applications in metal fabrication plants.

Zach Stewart, Kyle Harasimowicz, Jason Lizzo, Derrick Taylor, Brad Taylor, Jeremy Gaitsch, Michael Heine and Ed Diener at the Fluid-Aire Dynamics booth.

Nano has been a leader in factory-generated nitrogen and oxygen generation products. Industry veterans Jim McFadden and Matt McGuillin said they introduced the first modular in the market and that the new technologies are excited including the new NANO ecoGen2 and Gen2 Mini nitrogen generators. They confirmed demand has been strong and said the strength of their products has always been their simplicity and reliability.

Jim McFadden and Matt McGuillin next to the NANO ecoGen2 nitrogen generator.

Generon was displaying their NG Series modular nitrogen generator which is fild expandable up to 5 columns. Bruce Graham explained their carbon molecular sieve (CMS) towers use a high-end 400 mesh carbon, unlike some other products in the industry. Their units also feature a PLC able to provide trending reports and key performance indicators like inlet dew point and temperature. Generon also supplies oxygen generators using zeolite in the columns and said they are seeing growing demand for both product lines.

Steve Ciesin, John Gallo and Bruce Graham next to the NG Series nitrogen generator at the Generon booth (left to right).

ALKIN was founded in 1971 and is a manufacturer of high-pressure compressed air and breathing air compressors and nitrogen boosters with pressures up to 6000 psi. At Fabtech they were displaying their 530 Series booster for compressed air which goes up to 580 psi at very low rpms of 700-1000 which they say is 50-80% slower than many piston boosters on the market. They were also displaying their W32 nitrogen booster for pressures up to 6000 psi while extremely quiet at 60 dba.

Farren Choudry, Emre Tüjümet, Nitin Shanbhag and Gerardo Aburto Salas at the ALKIN booth (left to right).

Altec AIR continues their methodical march into standard industrial compressed air purification products. At Fabtech, they were presenting their HRL Series heatless desiccant dryer product line. They also have a very interesting “mini” heatless desiccant dryer for extremely low flow rates.

Jim DiMaiolo and Robert Ruskaup at the Altec AIR booth.

Tsunami Compressed Air Solutions displayed their point of use desiccant compressed air dryers and filters. They said their 15 cfm dryer is used in front of spray booths and plasma cutting tables in metal fabrication facilities. In addition their new Core Series cartridge style desiccant dryer has a maximum flow rating of 25 cfm.

Tara Eckhart, Mike Kreklau and Keisha Hernandez at the Tsunami Compressed Air Solutions booth (left to right).

Paul Cairney from South-Tek Systems is focused on the metal fabrication, stamping and welding market. He was discussing their LS Series nitrogen generators for lasers which provides an inlet nitrogen pressure to the laser of 400-500 psig. He was also presenting the HPF high pressure nitrogen booster package, rated for up to 4500 psi, and explained that laser cutting is an intermittent application for nitrogen and that users like to use nitrogen storage tanks.

Paul Cairney presented nitrogen generation systems at the South-Tek Systems booth.

Purity Gas was displaying their Nitrocenter nitrogen generator. Sales Manager Brett Rogers told me they place a large emphasis on conducting free nitrogen assessments for their clients. He said it’s very important to help clients double-check and verify key system requirements like nitrogen pressure, purity, flow, hours of operation. Continuing he said it’s also important to help clients understand the carbon impact and operational costs of the their current delivered gas systems.

Justin Marion and Brett Rogers next to the Nitrocenter at the Purity Gas booth (left to right).

Chiller Systems for Laser Cutting and Welding

Chase Cooling Systems was displaying their new QBE Series Chase Chiller designed for laser applications. The dual channel product line comes in 11 to 63 kW models for lasers up to 30 kW. Phil Shaver said the units have a new PLC controller. I liked the easy to see visual displays of the two chilled water temperature set-points for laser and optics.

Phil Shaver next to the new QBE laser chiller at the Chase Cooling Systems booth.

At every trade show I go to, I always discover at least one new company. This years’ discovery was Orion Chillers. Their U.S. operations are in Austin, Texas and they are a major OEM chiller supplier to most of the major metal stamping and fabrication manufacturers. After visiting their booth, I started noticing their chiller in the other booths. They said they were the first chiller manufacturer to introduce dual channel chillers for fiber laser applications. They have now introduced inverter technology to the pumps, fans and compressors in their chillers using 407c refrigerants.

Aruelle Fearn and Billy Pospisil at the Orion Chiller booth (left to right).

FABTECH 2024

Exclusively dedicated to advancing the metal forming, fabricating, welding, and finishing industries worldwide, FABTECH delivered an unparalleled trade show experience in 2023. The excitement and success of this year's event paves the way for a promising future. FABTECH 2024, which marks a shift in location, is scheduled for October 15-17, 2024, in Orlando, Florida, at the Orange County Convention Center. For more information, visit fabtechexpo.com .

For similar articles on Compressed Air Technology or Nitrogen Generators please visit https://www.airbestpractices.com/, For similar articles on Chillers please visit https://coolingbestpractices.com/.

Visit our Webinar Archives to listen to expert presentations on Compressed Air technology at

https://www.airbestpractices.com/webinars and Chiller technology at https://coolingbestpractices.com/magazine/webinars.