Introduction

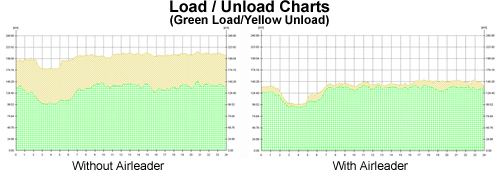

Compressed air is one of the most expensive energy sources used in our industrial plants. However, most compressed air systems have large energy savings potential. Easy-to-implement master control and monitoring systems provide crucial system information including the key performance indicators required to manage air compressors and their associated energy costs. Master control systems run air compressors based on actual air demand and automatically select the most energy efficient compressor combination. They reduce unwanted unload running time and wasted energy, regardless of air demand, and continuously provide essential compressed air performance and cost information.

Compressed air is one of the most expensive energy sources used in our industrial plants. However, most compressed air systems have large energy savings potential. Easy-to-implement master control and monitoring systems provide crucial system information including the key performance indicators required to manage air compressors and their associated energy costs. Master control systems run air compressors based on actual air demand and automatically select the most energy efficient compressor combination. They reduce unwanted unload running time and wasted energy, regardless of air demand, and continuously provide essential compressed air performance and cost information.

The Problem

Most segments of industry continue to have little information on what their compressed air system is doing. Little performance and efficiency data or cost information is available for a very expensive system. Accurate data to charge compressed air costs to different departments in the facility in not retrievable. It is common to have compressed air cost assigned to departments by using the amount of square feet the process or a department uses in the factory – not the amount of compressed air it uses! This provides no incentive to save compressed air at the department level.

Multiple air compressors are installed in most facilities. As the facility grows, more air compressors are added. It is common to see more than one air compressor room serving the facility with a complete lack of an overall air compressor control strategy.

Airleader Master Control and Monitoring |

The first Airleader air compressor control was invented twenty years ago in Germany by Mr. Werner Weidner of WF Steuerungstechnik GmbH. Mr. Weidner founded WF Steuerungstechnik GmbH with the clear company mission of improving the efficiency of air compressor systems through intelligent compressor controls. Today the Airleader product family consists of different air compressor controls, monitoring systems and data loggers for compressed air system audits. Based in southern Germany, the technology is private labeled for air compressor manufacturers, sold to distributors, and also delivered directly to end users as part of compressed air audits. Our tremendous success in Europe, with more than 6,000 sold units, as well as the positive feedback from our clients, dealers, and OEM customers, gave WF Steuerungstechnik the confidence to go overseas. In 2008 WF Steuerungstechnik GmbH partnered with SIGA Green Technologies to bring the Airleader product family to the North American market. The first Airleader air compressor control was invented twenty years ago in Germany by Mr. Werner Weidner of WF Steuerungstechnik GmbH. Mr. Weidner founded WF Steuerungstechnik GmbH with the clear company mission of improving the efficiency of air compressor systems through intelligent compressor controls. Today the Airleader product family consists of different air compressor controls, monitoring systems and data loggers for compressed air system audits. Based in southern Germany, the technology is private labeled for air compressor manufacturers, sold to distributors, and also delivered directly to end users as part of compressed air audits. Our tremendous success in Europe, with more than 6,000 sold units, as well as the positive feedback from our clients, dealers, and OEM customers, gave WF Steuerungstechnik the confidence to go overseas. In 2008 WF Steuerungstechnik GmbH partnered with SIGA Green Technologies to bring the Airleader product family to the North American market. |

Confusion over Compressor Controls

As awareness of the energy costs related to compressed air has grown, the end user has been bombarded with information about the on-board compressor controls. Each on-board air compressor controller can optimize the efficiency of that particular machine. Air compressor controllers include modulation, load/unload, inlet valve, and variable speed drive controls.

What the individual compressor controller cannot do, however, is work together with the unique demands of the factory and all the other installed air compressors in order to optimize energy efficiency. For this, the market offers net pressure cascading controls, various sequencers, and master controllers. All of these technologies can be effective in saving energy under specific operating circumstances. However, under different operating conditions, such as 2nd or 3rd shift, weekends or holidays, these technologies will not save energy.

Many factories we speak to are confused and frustrated by the lack of knowledge in how to appropriately deploy compressor control strategies. Some have installed sequencers but are not seeing energy savings and have turned them off. Others have purchased variable speed drive air compressors, but their energy bill has not been reduced. Many end users do not have the visibility they desire to manage the compressed air system or know if the control strategies they have purchased are working.

While the various compressor control technologies can deliver energy savings, the difficulty lies with the appropriate application. Plant conditions change and the compressor control can no longer deliver the original results. There can also be performance issues with specific air compressors that arise, which result in the control strategy not performing as desired.

|

kw/100 cfm is the Key Performance Indicator |

Technology Simplifies the Solution

My personal experience comes from working as a manager and engineer in Tier 2 automotive suppliers. We recognized compressed air was a critical “4th Utility” in the facility. We focused primarily on whether or not we had enough compressed air to produce our products. We knew we spent a lot of money to power the air compressors but we did not have any visibility into these costs.

The Airleader family of Master Control and Monitoring products provides the solution. The Master Controller will optimize compressor performance automatically, while the Monitoring provides the data required for a manager to visualize and manage the compressed air system from their office.

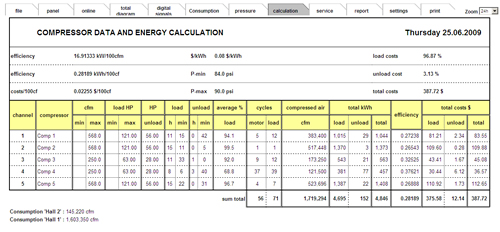

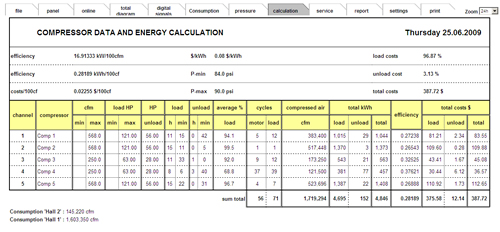

Compressor Data and Energy Calculation, provides detail to optimize compressed air system and keep them that way.

The Key Performance Indicator (KPI): kW/100 cfm

While the Airleader software can produce many reports on different areas, we recommend that managers focus on one Key Performance Indicator (KPI): kW/100 cfm. This represents how much energy (in kW) is used to deliver how much air flow (cfm). The Airleader provides the tools required to monitor this KPI for the entire facility and for each air compressor.

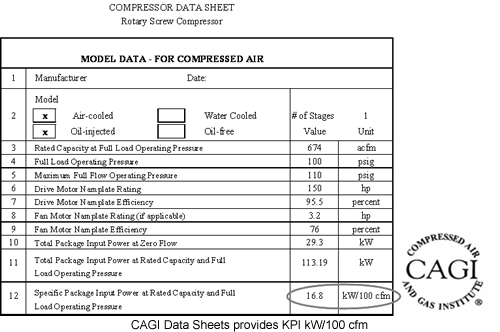

Another advantage to using kW/100 cfm as a KPI is that air compressor suppliers can provide you this number. Members of the Compressed Air and Gas Institute (CAGI) supply “CAGI Data Sheets” with their air compressor products. Virtually all major air compressor manufacturers are members of CAGI (www.cagi.org). This allows the end user to get an “apples-to-apples” comparison of air compressors when buying new ones. More importantly, it allows an end user to benchmark their system and control if the factory-achieved KPI of kW/100 cfm is close to what the performance rating states on the CAGI Data Sheet.

The Airleader Master Controller documents which air compressors are most efficient. Each unit is monitored and the manager is given a detailed report including a kW/100 cfm for every air compressor. As circumstances in the plant or with the air compressor change, the Master Controller measures and monitors the performance of each compressor and of the system. If the performance of a compressor deteriorates, the Master Controller provides information and alerts.

Factories Should Use kW/100 cfm as a Key Performance Indicator

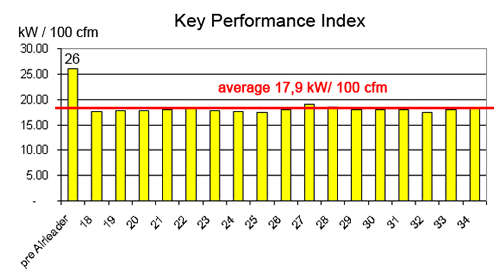

The charts Key Performance Index shows that after the installation of the Master Control the KPI improved from 26 kW / 100 cfm to 17,8 kW/100 cfm. Whatever changes and improvements we did to the system in the following weeks, the system always adjusted and the KPI averaged around 17.9 kW/100 cfm. System Monitoring is the only way to assure that your control delivers the promised results.

Accumulated Intelligence Makes it Easy to Save

The primary advantage of a Master Controller is that it will automatically recognize changes in the demand side (air demand) and intelligently choose which components of the supply side (the air compressors) of the system can meet the changed demand most efficiently.

|

"Master control systems run air compressors based on actual air demand and automatically select the most energy efficient compressor combination." - Jan Hoetzel, SIGA Green Technologies |

The intelligence of a Master Controller is invaluable as it will select the best combination for each unique air demand situation. The Airleader Master Control comes with an eight-fold learning window. Over time the master control learns the overall system dynamic and based upon the speed of pressure change determines whether to turn on a big or small compressor. Depending if Pmax or Pmin is approached very quickly or slowly, the Master Controller has the accumulated intelligence to decide which compressor is the appropriate compressor to bring on or turn off, thereby assuring best energy results.

In contrast, a sequencer has a rigid pressure band and simply takes the next compressor on-line e.g. a 200 hp compressor #2 which is pre-programmed. If Pmin is approached very slowly, the Master Controller might take on e.g. compressor #3 which is only a 50 hp compressor. This can create a significant reduction in unloaded power consumption and load cycling. We have seen many cases where a sequencer has a large compressor e.g. 200 HP programmed as base load compressor and during off hours this compressor is running very inefficiently, while a smaller 50 HP compressor would be sufficient.

The Master Controller has no base load compressor; each compressor in the system can act as the base load, peak load or operate on its own. The Airleader Master Control will learn and adapt automatically to changes in the system, whether additional storage tanks are added or air usage is changing. One of the primary benefits is that the Master Controller will automatically reduce no-load energy consumption.

Control Strategies

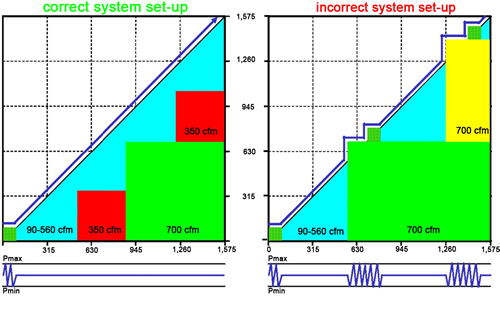

Many sites we have evaluated have installed variable speed drive (VSD) compressors but have not achieved the desired energy savings. The VSD compressor and the rest of the compressors do not interact and/or are improperly sized. We, at Airleader, developed a tool to simulate system performance, assuring the compressors are sized correctly to provide the most economical and energy efficient solution. We provide this simulation to our partners, dealers and clients. A properly designed system with a VSD compressor run by an Airleader Master Control can achieve as little as 0.1% unload energy, for a system without a VSD compressor, the unload energy can be as low as 1%. The following graphs show the simulation of correct and incorrect system set-up.

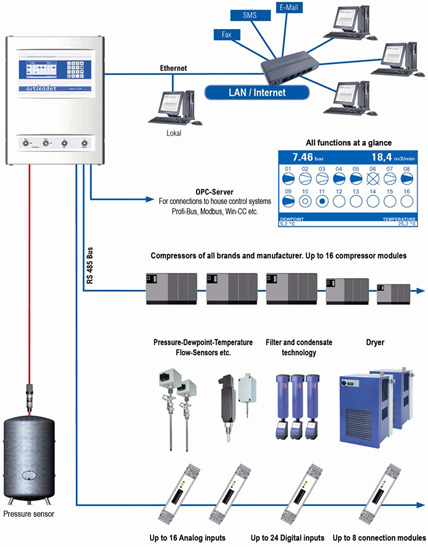

Gathering Data

The Airleader Master Controller has up to 52 analog inputs and 24 digital inputs. The Airleader CN is another model with 132 analog and 96 digital inputs. It acts as “the brain” where many, many pieces of information about the compressed air system can be sent and analyzed.

|

"The Airleader family of products includes a data logger specifically designed for compressed air systems." - Jan Hoetzel, SIGA Green Technologies |

Various analog sensors and digital signals can be added to increase awareness, to alert or to improve preventive maintenances. Additional pressure transducers to monitor plant pressure in various locations or differential pressure transducers are very useful to monitor pressure drop on compressed air filters.

Three-phase transducers measure the exact kW consumption of every air compressor and “learn” how the air compressor performs under different circumstances.

Flow meters are important if you want to charge different departments for their individual compressed air usage. Flow is the way to truly measure the compressed air consumption in each area. We tie flow meters into the Master Controller and this allows our customers to finally charge each department according to use– not square footage!

Compressed air dew-point can be monitored with information sent from a dew-point meter. Alarm functionality exists in which plant personnel can receive an alarm e-mail if dew-point suffers. Zero air-loss condensate drains can also communicate with the Master Controller and provide alarms if there is a malfunction. Process temperature gauges can also communicate with the Master Controller and trigger alarms if, for example, cooling water temperatures are too high which will cause the air compressors to overheat or shut down. This allows for preventive maintenance and emergency shut downs can be averted.

Compressed air dryers can also be connected to communicate with the Master Controller.

Communicating the Data

The air compressors communicate with the Master Controller via a RS 485 Module. The Web based system can be accessed remotely via VPN Clients worldwide. The OPC (open connectivity) Interface allows data transfer to all types of in-house control systems; supporting Profi-Bus, Modbus, Win-CC and others.

The Airleader family of products includes a data logger specifically designed for compressed air systems. This data logger comes with a software package that generates reports with tables, graphs and evaluates the KPI KW /cfm for system benchmarks that are needed to analyze the status quo of compressed air systems and make continuous improvements.

Conclusion

A Master Control will assure that your air supply side (the air compressors) will automatically and most efficiently follow compressed air demand in the plant. The monitoring system keeps track of system performance and cost information. It shows the results of improvement efforts and lets you immediately verify the savings, e.g. from a leak project.

Managers can monitor the system and charge different departments appropriately for their air consumption based upon flow. KPI Key Performance Index kW/100 cfm can be monitored and managed and alarms can be set to notify managers of system malfunctions or of increases in costs.

For more information contact Jan Hoetzel, Airleader USA. Tel (616) 828-0716. jan@airleader.us, www.airleader.us.