What kind of mobile phone are you using? Look around. Is anyone using the original “brick phones,” or Blackberries or even Palm Treos? Can you remember seeing any of these classic phones in recent years? Sure there are a few diehards still hanging on to their old phones, but the vast majority of people are using some brand of the latest smartphone.

Why are we continually switching to new phones? The answer is simple. Advances in phone technology dramatically improve their function and our experience. More storage, faster speeds, enhanced communication options, bigger and brighter display….and so on. As a result, today’s phones are significantly more powerful – improving our productivity and changing our lives. As for the technology laggards, obsolescence eventually prompts change. Repairing or replacing parts and accessories on the old phones is an increasing challenge. Eventually they have to succumb to technology.

Air Compressor Master Controls to Prevent Control Gap – Webinar RecordingDownload the slides and watch the recording of the FREE webcast to learn:

|

What is interesting is that while individuals have embraced new technology for personal use, many of these same individuals work for companies that operate air compressors that have antiquated and often, obsolete controllers. Just like cell phones, air compressor controls have advanced over the years – providing similar benefits.

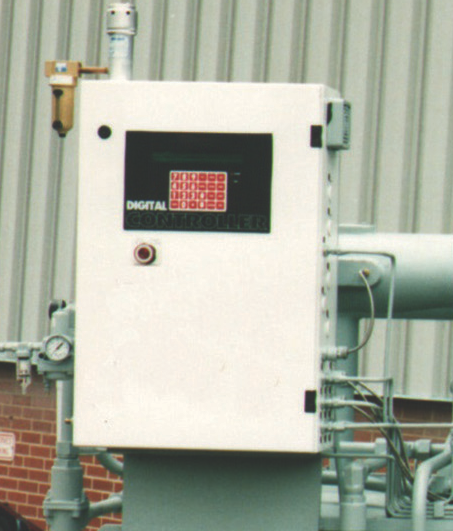

Retro air compressor controller.

Modern air compressor controller.

New air compressor controls deliver differentiated benefits that can include productivity, reliability, ease of use and system integration. The parallels to mobile phone advances are obvious.

- Enhanced displays: Larger displays, brighter colors and screens that are more intuitive give users easier access to key information. Navigation to additional screens and settings is very simple – saving time.

- Increased memory and processor speed: Having the ability to store more historical data enables better performance tracking and helps with potential troubleshooting.

- Critical communication: Keeping in touch with your air compressor remotely is effectively accomplished through web pages. Automated reporting and alert emails keep users informed of key parameters at all times.

- Expanded connectivity: Greater flexibility with multiple options to connect the air compressor with a customer’s DCS, system controls, LAN/Web access, and technician service tool.

- Optimized efficiency: Improved algorithms and control logic ensure the air compressor efficiency is maximized at all times.

- Improved reliability: Maintaining existing obsolescent controls is a challenge and can affect reliability. Access to parts and repairs continues to diminish over time as components become obsolete. Upgrading to current controls removes that risk to reliability. Many manufacturers make it simple to upgrade to the latest controls with pre-engineered plug and play solutions. Retrofits can be completed in as low as four hours for some models. Perhaps easier than upgrading your phone with the cellular provider….no complicated billing plans or rigid contracts to sign!

|

The Compressed Air and Gas Institute (CAGI) is the united voice of the compressed air industry, serving as the unbiased authority on technical, educational, promotional, and other matters that affect compressed air and gas equipment suppliers and their customers. CAGI educational resources include e-learning coursework, selection guides, videos and the Compressed Air & Gas Handbook. The Centrifugal Compressor Section consists of the following member companies:

|

For more information, visit the CAGI web site at www.cagi.org.

All photos courtesy of the Compressed Air and Gas Institute.

To read more Air Compressor Instrumentation articles, please visit www.airbestpractices.com/technology/instrumentation.