System Assessments

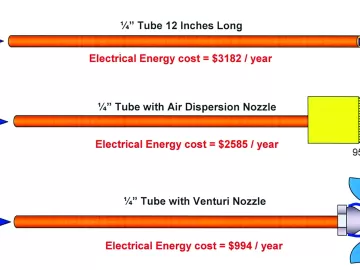

Given that compressed air leak management programs are meant to save energy, reduce CO2 emissions, and generate ROI, DENSO’s Maryville, Tennessee, manufacturing facility can definitively say it has scored a trifecta when it comes to results – and reaped benefits beyond hard numbers alone.