Evaluating Different Blower Technologies on a Wire-to-Air Basis

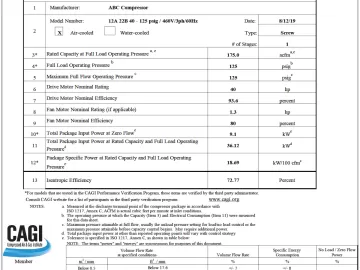

In the absence of official third party specifications on energy efficiency, it is difficult to evaluate and compare blower technologies fairly and effectively. The lack of readily available evaluation tools leads to misinformation and unfair comparisons between technologies. Further, the performance verification process is difficult to prove.